Digital Workshop FabLab Brno

Default Ideas

The well-lit room with high ceilings and a skylight originally served as an art studio for FAVU. The generous space allowed for vertical engagement with the environment, and thanks to the wooden installations, the author created enough independently separated spaces for working with various technologies (laser cutter, 3D printers, programmable embroidery machine, cutting plotter) as well as a separate workshop for woodworking.

The central part of the room offers variability for lectures, educational activities, and community events due to the sliding and folding tables. The current use of the space thus continues the educational tradition and is largely dedicated to hosting workshops and educational courses in digital technologies for the public.

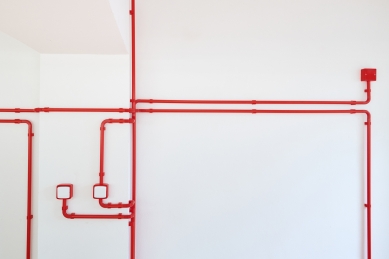

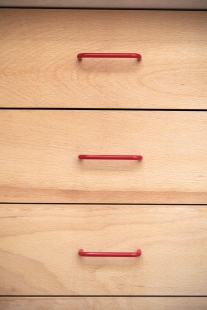

An accompanying feature of the design is the curved pipes and their various applications. Red pipes for routing electrical wiring upstairs without the need to cut into the walls, railings, and details like door handles or cabinet knobs. White ones serve as legs for tables and chairs. The repeating red color in the interior complements the light wooden structure of the installations and visually integrates into the identity of FabLab Brno.

The design retains a reference to the room’s history and harmoniously combines new wooden constructions, modern elements, and technologies with the concrete, paint-splattered floor, door, as well as a few small messages written on the walls. The revitalized school chairs also align with the educational institution's purpose.

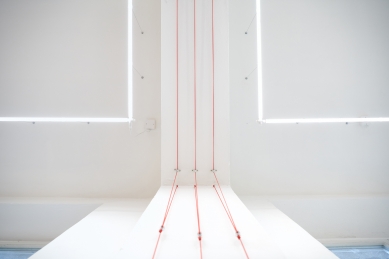

The architect's design includes details for connecting electrical installation components, anchoring railings, and hidden mounting of polycarbonate fillings. An original feature of the interior is a simple system of suspended extension cords from the ceiling, which can be easily lowered or raised according to the current needs of the space using a straightforward pulley system.

FabLab made in Fab

In realizing the design, the author utilized technologies that are part of the digital workshop (especially 3D printing), enabling great freedom in addressing details. All elbow joints of the red pipes for electrical installations are 3D printed, as well as penetrations for troughs or connected devices. Through 3D printing, handles for pipes and lights were also created, which are not produced in the desired shades or did not allow for ceiling suspension, as well as details for attaching bases to tables, ending ventilation, and clips for routing extension cords along the ceiling to doorstops.

Thanks to the workshop's craft equipment, the author, along with assistants, created worktops, including the construction of an entire workbench, tables, a window seat bench, window sills connecting to shelves for 3D printers, and additional storage spaces.

The Result

The architect found herself in a unique position where she not only had the opportunity to develop the design and oversee the construction process but also utilize her experiences with technologies and crafts to engage in the production of larger interior elements and individual details on-site. The actual realization of the project thus corresponds with the main function of FabLabs - to support the ability of people to transform their ideas into reality through modern technologies.

The well-lit room with high ceilings and a skylight originally served as an art studio for FAVU. The generous space allowed for vertical engagement with the environment, and thanks to the wooden installations, the author created enough independently separated spaces for working with various technologies (laser cutter, 3D printers, programmable embroidery machine, cutting plotter) as well as a separate workshop for woodworking.

The central part of the room offers variability for lectures, educational activities, and community events due to the sliding and folding tables. The current use of the space thus continues the educational tradition and is largely dedicated to hosting workshops and educational courses in digital technologies for the public.

An accompanying feature of the design is the curved pipes and their various applications. Red pipes for routing electrical wiring upstairs without the need to cut into the walls, railings, and details like door handles or cabinet knobs. White ones serve as legs for tables and chairs. The repeating red color in the interior complements the light wooden structure of the installations and visually integrates into the identity of FabLab Brno.

The design retains a reference to the room’s history and harmoniously combines new wooden constructions, modern elements, and technologies with the concrete, paint-splattered floor, door, as well as a few small messages written on the walls. The revitalized school chairs also align with the educational institution's purpose.

The architect's design includes details for connecting electrical installation components, anchoring railings, and hidden mounting of polycarbonate fillings. An original feature of the interior is a simple system of suspended extension cords from the ceiling, which can be easily lowered or raised according to the current needs of the space using a straightforward pulley system.

FabLab made in Fab

In realizing the design, the author utilized technologies that are part of the digital workshop (especially 3D printing), enabling great freedom in addressing details. All elbow joints of the red pipes for electrical installations are 3D printed, as well as penetrations for troughs or connected devices. Through 3D printing, handles for pipes and lights were also created, which are not produced in the desired shades or did not allow for ceiling suspension, as well as details for attaching bases to tables, ending ventilation, and clips for routing extension cords along the ceiling to doorstops.

Thanks to the workshop's craft equipment, the author, along with assistants, created worktops, including the construction of an entire workbench, tables, a window seat bench, window sills connecting to shelves for 3D printers, and additional storage spaces.

The Result

The architect found herself in a unique position where she not only had the opportunity to develop the design and oversee the construction process but also utilize her experiences with technologies and crafts to engage in the production of larger interior elements and individual details on-site. The actual realization of the project thus corresponds with the main function of FabLabs - to support the ability of people to transform their ideas into reality through modern technologies.

AD Crafts

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment