Mikimoto Ginza 2

|

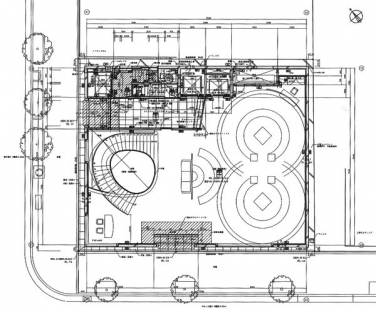

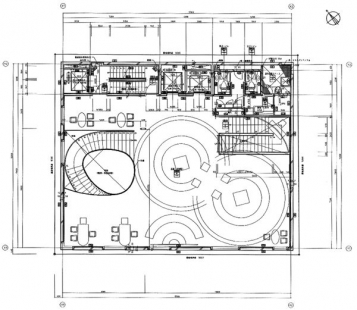

This commercial building in Tokyo's Ginza district was designed for the Mikimoto company, which is renowned worldwide for its pearl jewelry. It is a rectangular building (17 m wide and 14 m deep) with nine above-ground floors and one basement. The lower levels will serve the Mikimoto company for retail and offices. The upper floors will be rented out as office spaces.

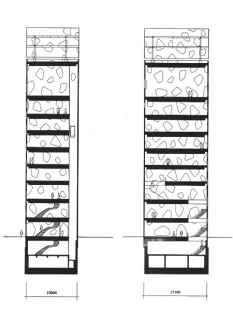

Mikimoto Ginza 2 is enveloped in four thin walls creating a tubular structural system. There are no internal columns, and the ceilings consist of nine homogeneous layers. In previous projects (Tod’s), the structure was an integral part of the building that manifested itself externally as well. Here, a steel-concrete structure forms the facade, where concrete was poured between two steel plates. Sandwich panels made of steel plates (thickness 6-12 mm), fixing elements, and reinforcement were assembled at the factory and then transported to the construction site. After raising and welding the panels together, concrete was poured into the 200 mm wide space between the steel plates. This system, which incorporates steel plates that originally served as formwork further into the structure, allows for the creation of extremely thin structures while maintaining strength and durability. Because this is also a non-directional flat structural system, holes can be placed in them completely arbitrarily. Irregular, almost crystal-shaped openings in the facade were created by conceptually dividing the facade panels with seven triangles each time. The combination of a grid of "liquid" (as if capturing the moment of flow) windows with an unusual structure of the outer shell allows the building to express both lightness and tension simultaneously. The design is not based purely on geometry, does not follow structural or construction processes, and instead employs new methods. For the first time, the entire project was successfully realized using a method known as the 'finite element method'.

To achieve a flat seamless facade, the seams on-site were smoothly sanded and the steel plates were painted multiple times, from anti-corrosion coating to topcoat. After the joints that can normally be found on outer shells were removed, the outer appearance of the house was stripped of materiality, abstracted, and uniquely yet directly expresses the solidity of the structure.

El Croquis 123, pp. 342-349.

In conclusion, I would like to thank Rempei Goto for the provided photographs and helpful information about the construction.The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment