Sawmill House

Befitting a regionally based sculptor, the Sawmill House is a hand crafted upgrade from his existing rather rustic, bohemian abode and is a demonstration of how Australia’s growing hoard of latent building materials can be used in new and innovative ways.

Located on the site of an old sawmill, which fell into remission in the late 90s, the Sawmill House is the result of a close connection between the client and the architect, brothers with a shared creative vision. The established relationship, encouraged the design to slowly develop over the course of construction, allowing for immediate feedback to challenges faced. Working closely with the client and embracing his skill set – a builder and sculptural artist – the house moved away from conventional design solutions towards more bespoke and cost effective alternatives.

270 recycled blocks to form the perimeter walls. Each block weighs around one tonne and are locally produced from the by-product of concrete slabs poured in the region, creating an experiment in leveraging the thousands of tonnes of concrete that go to waste each year. These blocks create a patchwork of colour and texture across the facades, as each block has a story; a bridge, a footpath, a home. This texture grounds the building in the site, as the layers of colour mimic the sedimentary layers of earth still exposed from the site’s former life as a gold mine. This approach contributes to a broader conversation around reuse, encouraging investment and investigation into the largely untapped resource of latent assets.

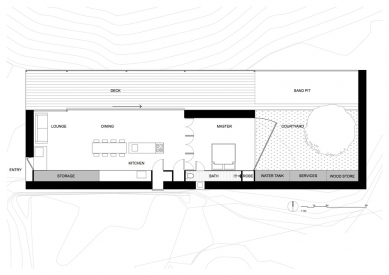

Large sections of the roof and façade were mechanised so the clients could add and subtract natural light as the seasons changed. The home’s external decking area offers views of an old dam through double glazed stacking doors spanning the kitchen and living rooms.

To pay homage to the site’s previous use as a sawmill the floor and ceiling has been lined in locally sourced red stringy bark and narrow leaf peppermint timbers. The concrete blocks are largely left exposed and raw while the joinery has been wrapped in a patinated brass sheet that will continue to change over time.

In order to learn the most from the process members of the architecture team designed and built the furniture, light fittings, joinery and hardware in a hands on approach that focused on ‘learning by making’.

Located on the site of an old sawmill, which fell into remission in the late 90s, the Sawmill House is the result of a close connection between the client and the architect, brothers with a shared creative vision. The established relationship, encouraged the design to slowly develop over the course of construction, allowing for immediate feedback to challenges faced. Working closely with the client and embracing his skill set – a builder and sculptural artist – the house moved away from conventional design solutions towards more bespoke and cost effective alternatives.

270 recycled blocks to form the perimeter walls. Each block weighs around one tonne and are locally produced from the by-product of concrete slabs poured in the region, creating an experiment in leveraging the thousands of tonnes of concrete that go to waste each year. These blocks create a patchwork of colour and texture across the facades, as each block has a story; a bridge, a footpath, a home. This texture grounds the building in the site, as the layers of colour mimic the sedimentary layers of earth still exposed from the site’s former life as a gold mine. This approach contributes to a broader conversation around reuse, encouraging investment and investigation into the largely untapped resource of latent assets.

Large sections of the roof and façade were mechanised so the clients could add and subtract natural light as the seasons changed. The home’s external decking area offers views of an old dam through double glazed stacking doors spanning the kitchen and living rooms.

To pay homage to the site’s previous use as a sawmill the floor and ceiling has been lined in locally sourced red stringy bark and narrow leaf peppermint timbers. The concrete blocks are largely left exposed and raw while the joinery has been wrapped in a patinated brass sheet that will continue to change over time.

In order to learn the most from the process members of the architecture team designed and built the furniture, light fittings, joinery and hardware in a hands on approach that focused on ‘learning by making’.

9 comments

add comment

Subject

Author

Date

Konečně něco pěkného

Petr Skácel

11.04.19 04:38

Rána do srdce

Eva Chrobáková

11.04.19 10:45

Úžasné !

cztodo

11.04.19 04:48

Naprostý souhlas

helenabox

11.04.19 08:03

skvela prace

Novotny

12.04.19 10:09

show all comments