Tiny House LUX

Solution to the Housing Crisis through Innovations

Luxembourg, like many other countries around the world, is facing a growing housing crisis. Every year approximately 7,000 new housing units are needed to meet demand. The reality, however, is different, with barely half of that number being created. Out of this, only about 200 are available or public housing units. In this context, municipalities are starting to look for new ways to utilize even unutilized urban land and offer new forms of affordable housing.

It was from this need that the Tiny House LUX project was born, an idea by architect Bujar Hasani from ODA Architects in collaboration with the municipality of Niederanven. The project focuses on small residual plots in cities that regular construction cannot utilize due to strict spatial restrictions. Architect Hasani viewed them differently. Instead of considering them as unbuildable, he sees them as an opportunity for a new type of compact and sustainable housing.

The concept was approved by the municipality based on a shared vision: to create small, high-quality homes for young residents who wish to stay in their community. Thus, the solution responds not only to spatial and environmental challenges but also to social ones while respecting local roots in a rapidly changing housing situation.

Unlike many conventional “tiny house” models, Tiny House LUX was never intended as a temporary structure. From the very beginning, it was about providing full-fledged housing with the same construction and thermal parameters as a traditional house in Luxembourg, utilizing modern technologies, including 3D printing as a means to achieve higher construction quality without compromises.

To successfully realize the concept and also enable its repetition elsewhere in the future, ODA Architects decided on concrete 3D printing technology. The partner became the Czech company ICE Industrial Services with its division Coral Construction Technologies, which specializes in innovative construction methods and their practical applications. ICE, which focuses on industrial automation, established the Coral platform in 2021 to seek new solutions for concrete 3D printing. Thus, the Tiny House project combined architectural vision with technical innovation, enabling the realization of digital designs with exceptional precision and efficiency directly on the construction site.

Pilot Project, A House on Three Meters

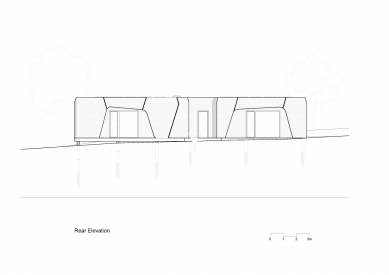

The first test house was created on a narrow and previously unused plot on the edge of a residential area in Niederanven. Due to local regulations, the assigned plot had a significantly elongated shape, with a width of 3.5 meters and a depth of 17.7 meters, leading to a compact and efficient layout with a usable area of 47 m².

Given the minimal external width of just three meters, the architectural concept focused on creating a strong linear axis that visually expands the space. By placing functional elements on both sides of storage areas, furniture, and technical zones and maintaining an open central perspective, the interior achieves a sense of depth and spatial clarity that far exceeds its compact dimensions. The result is a balanced, elongated composition that, despite its size, feels cohesive and calm.

The Tiny House in Luxembourg is a pioneer also from a technical standpoint: it is the first 3D printed residential building utilizing local construction materials and stands on a wooden foundation slab on ground screws, without the use of traditional concrete foundations.

Technology and Construction

The entire process followed the principle of “design & build”. The architects designed the shape and function, while the Coral team translated the design into a digital model and prepared all data for robotic printing.

The Coral printer is unique worldwide in that it can print directly on the construction site and utilizes standard concrete from a local concrete plant. Unlike industrially produced dry mixes, this approach is more cost-effective and environmentally friendly, as it allows for the use of materials from the immediate vicinity, significantly reducing transportation-related emissions. The printing itself takes approximately one week, while the entire construction, including finishing works, can be completed in an incredible four weeks.

Another advantage of 3D printing is the ability to integrate technical details directly during the printing process. For example, the shower or toilet space was printed as part of the load-bearing structure, eliminating the need for additional interventions after the construction was completed, which enhances functionality and spatial precision.

Sustainability and Materials

The house stands on a wooden foundation structure, complemented by a lightweight wooden roof that reduces the overall weight of the construction and simplifies any future dismantling or relocation. Insulation and reinforcements are of mineral origin without the use of synthetic components. The result is a building that can be easily disassembled, relocated, and recycled, thus meeting the goals of circular and ecological construction.

3D printing also utilizes only as much material as is truly needed. This means not only reduced consumption of raw materials but also a lower carbon footprint. Solar panels are installed on the roof, providing electricity for the operation of the house and underfloor heating. Thanks to the south-facing windows, the house naturally harnesses solar energy and minimizes the need for additional heating.

Significance and Repeatability

The Tiny House LUX project is not just an experiment; it is a real model of compact and sustainable housing that can be easily replicated elsewhere. It was created with the full support of the municipality of Niederanven, which provided the framework for verifying this alternative construction approach on public land.

The project combines digital production, local materials, and modular logic, resulting in an affordable, ecological, and easily replicable form of modern housing.

Ultimately, Tiny House LUX proves that tradition and innovation can go hand in hand. That even modern cutting-edge technologies, such as concrete 3D printing, can align with local craftsmanship and architectural traditions that are rooted in Luxembourgish society.

Luxembourg, like many other countries around the world, is facing a growing housing crisis. Every year approximately 7,000 new housing units are needed to meet demand. The reality, however, is different, with barely half of that number being created. Out of this, only about 200 are available or public housing units. In this context, municipalities are starting to look for new ways to utilize even unutilized urban land and offer new forms of affordable housing.

It was from this need that the Tiny House LUX project was born, an idea by architect Bujar Hasani from ODA Architects in collaboration with the municipality of Niederanven. The project focuses on small residual plots in cities that regular construction cannot utilize due to strict spatial restrictions. Architect Hasani viewed them differently. Instead of considering them as unbuildable, he sees them as an opportunity for a new type of compact and sustainable housing.

The concept was approved by the municipality based on a shared vision: to create small, high-quality homes for young residents who wish to stay in their community. Thus, the solution responds not only to spatial and environmental challenges but also to social ones while respecting local roots in a rapidly changing housing situation.

Unlike many conventional “tiny house” models, Tiny House LUX was never intended as a temporary structure. From the very beginning, it was about providing full-fledged housing with the same construction and thermal parameters as a traditional house in Luxembourg, utilizing modern technologies, including 3D printing as a means to achieve higher construction quality without compromises.

To successfully realize the concept and also enable its repetition elsewhere in the future, ODA Architects decided on concrete 3D printing technology. The partner became the Czech company ICE Industrial Services with its division Coral Construction Technologies, which specializes in innovative construction methods and their practical applications. ICE, which focuses on industrial automation, established the Coral platform in 2021 to seek new solutions for concrete 3D printing. Thus, the Tiny House project combined architectural vision with technical innovation, enabling the realization of digital designs with exceptional precision and efficiency directly on the construction site.

Pilot Project, A House on Three Meters

The first test house was created on a narrow and previously unused plot on the edge of a residential area in Niederanven. Due to local regulations, the assigned plot had a significantly elongated shape, with a width of 3.5 meters and a depth of 17.7 meters, leading to a compact and efficient layout with a usable area of 47 m².

Given the minimal external width of just three meters, the architectural concept focused on creating a strong linear axis that visually expands the space. By placing functional elements on both sides of storage areas, furniture, and technical zones and maintaining an open central perspective, the interior achieves a sense of depth and spatial clarity that far exceeds its compact dimensions. The result is a balanced, elongated composition that, despite its size, feels cohesive and calm.

The Tiny House in Luxembourg is a pioneer also from a technical standpoint: it is the first 3D printed residential building utilizing local construction materials and stands on a wooden foundation slab on ground screws, without the use of traditional concrete foundations.

Technology and Construction

The entire process followed the principle of “design & build”. The architects designed the shape and function, while the Coral team translated the design into a digital model and prepared all data for robotic printing.

The Coral printer is unique worldwide in that it can print directly on the construction site and utilizes standard concrete from a local concrete plant. Unlike industrially produced dry mixes, this approach is more cost-effective and environmentally friendly, as it allows for the use of materials from the immediate vicinity, significantly reducing transportation-related emissions. The printing itself takes approximately one week, while the entire construction, including finishing works, can be completed in an incredible four weeks.

Another advantage of 3D printing is the ability to integrate technical details directly during the printing process. For example, the shower or toilet space was printed as part of the load-bearing structure, eliminating the need for additional interventions after the construction was completed, which enhances functionality and spatial precision.

Sustainability and Materials

The house stands on a wooden foundation structure, complemented by a lightweight wooden roof that reduces the overall weight of the construction and simplifies any future dismantling or relocation. Insulation and reinforcements are of mineral origin without the use of synthetic components. The result is a building that can be easily disassembled, relocated, and recycled, thus meeting the goals of circular and ecological construction.

3D printing also utilizes only as much material as is truly needed. This means not only reduced consumption of raw materials but also a lower carbon footprint. Solar panels are installed on the roof, providing electricity for the operation of the house and underfloor heating. Thanks to the south-facing windows, the house naturally harnesses solar energy and minimizes the need for additional heating.

Significance and Repeatability

The Tiny House LUX project is not just an experiment; it is a real model of compact and sustainable housing that can be easily replicated elsewhere. It was created with the full support of the municipality of Niederanven, which provided the framework for verifying this alternative construction approach on public land.

The project combines digital production, local materials, and modular logic, resulting in an affordable, ecological, and easily replicable form of modern housing.

Ultimately, Tiny House LUX proves that tradition and innovation can go hand in hand. That even modern cutting-edge technologies, such as concrete 3D printing, can align with local craftsmanship and architectural traditions that are rooted in Luxembourgish society.

ODA Architects

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment