Gläserne Manufaktur

The Volkswagen AG company has decided as part of its strategic objectives to enter the luxury car category. For the vehicle named "Phaeton," it was decided to build an entirely new production facility with parameters that had not been used before in the automotive manufacturing sector. The Saxon city of Dresden was chosen for the realization of this unique concept. The location of the prestigious Volkswagen AG vehicle factory in the territory of the former GDR had not only purely economic aspects but also one significant social aspect; it exemplified the reunification of Germany.

The fundamental task for architects and designers was to create a concept and subsequent construction realization that would allow the customers as well as the audience of automotive enthusiasts to witness the final assembly of the high-class model "Phaeton." The concept of the new factory will also enable a "staged" delivery of the vehicle to the customer. For this reason, a completely transparent solution for the building was proposed, both from the interior and the exterior. The unique "Experience Space" serves not only to deliver the product to the customer but also informs through technical simulations about the themes of "car," "VW group," or offers use for various cultural programs.

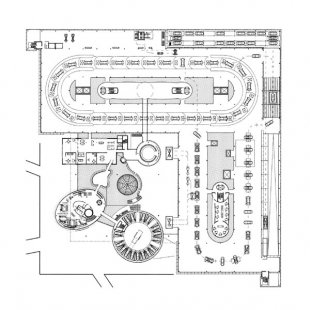

The quadrangular complex of the factory is located within sight of the city center at Strasbourg Square, which was part of the exhibition grounds destroyed during the war. The complex is bordered by the "Great Garden" with extensive park-like modifications and the former Garden Palace from 1680. One of the prerequisites for the release and selection of the location was also the promise of emission-free production and favorable transportation of prefabricated automotive parts from a logistics center on the outskirts of the city. For this purpose, specially developed "Cargo tram trains" operate on the tracks of urban transport. The factory production is essentially a symbol of a partial departure from the "Athens Charter," which defines the spatial division of residential zones and industrial production.

The multi-story concept of the manufacturing area, incorporating the "Experience Zone," derives from both the possibilities of the land and the situation of urban development on one hand and from the functional flow of final assembly and the opportunity to participate in the final assembly "with one’s own eyes" on the other. Strasbourg Square, the intersection of two heavily trafficked streets, is now completed on the southeast side by a 22 m high body of the production area, situated in a rectangular form facing northeast and southeast. In the corner of this "active zone," a large terrace runs over the lower floor. Large glassed areas of the terrace open views of the city center and green gardens. They are divided by a 40 m high "vehicle cylinder," a section for vehicle dispatch, a customer "lounge," and a small administration wing. Access to the terrace and the "Experience Zone" and potential exit for completed vehicles is created by a light bridge over artificial water bodies. Prefabricated automotive parts are delivered to the underground yard in the southeast part of the production area.

In the "Experience Zone," the external single-shell glass wall is made of standard Schüco-FW50+ construction, a modular structure with insulating glazing. The load-bearing structure consists of steel pipes. In the "Manufacturing Area," the outer layer of the double facade is again made based on standard Schüco modular construction on massive flat steel profiles without a thermal bridge, suspended on steel arms anchored to the ceiling slab. The inner shell, which thermally separates the exterior space from the "Active Zone," is made of special Schüco profiles with insulating glazing. These profiles are secured with prestressed cables of stainless steel to take up vertical and horizontal forces. This solution allows the external and internal shells to be constructed with minimal static cross-section, making the structure appear very elegant and delicate.

The manufacturing area is fitted in the southeastern and southwestern corner with a double facade due to the need for temperature regulation depending on external climatic conditions. The overall value of the heat transfer coefficient is k=1.2, and the level of energy transfer when fully utilizing the awning slats reaches a value of 0.11.

The text by Karla Doležela (Berlin Notebook, Architect 10/2002, pp. 68-70) prompted me to write an article about Prof. Henn, where he was necessarily overshadowed in comparison to Lord Foster. Prof. Dr. Günther Henn is, however, the head of the Institute of Industrial Building at the Technical University in Dresden. He owns a successful architectural office in Berlin and Munich. I had the opportunity to attend his lectures, where he willingly and engagingly shared his experiences. His work is encapsulated in operational schemes and graphs of industrial buildings, yet even in this position, he manages to innovate, come up with remarkable ideas, and sell them with his self-assured demeanor.

The fundamental task for architects and designers was to create a concept and subsequent construction realization that would allow the customers as well as the audience of automotive enthusiasts to witness the final assembly of the high-class model "Phaeton." The concept of the new factory will also enable a "staged" delivery of the vehicle to the customer. For this reason, a completely transparent solution for the building was proposed, both from the interior and the exterior. The unique "Experience Space" serves not only to deliver the product to the customer but also informs through technical simulations about the themes of "car," "VW group," or offers use for various cultural programs.

The quadrangular complex of the factory is located within sight of the city center at Strasbourg Square, which was part of the exhibition grounds destroyed during the war. The complex is bordered by the "Great Garden" with extensive park-like modifications and the former Garden Palace from 1680. One of the prerequisites for the release and selection of the location was also the promise of emission-free production and favorable transportation of prefabricated automotive parts from a logistics center on the outskirts of the city. For this purpose, specially developed "Cargo tram trains" operate on the tracks of urban transport. The factory production is essentially a symbol of a partial departure from the "Athens Charter," which defines the spatial division of residential zones and industrial production.

The multi-story concept of the manufacturing area, incorporating the "Experience Zone," derives from both the possibilities of the land and the situation of urban development on one hand and from the functional flow of final assembly and the opportunity to participate in the final assembly "with one’s own eyes" on the other. Strasbourg Square, the intersection of two heavily trafficked streets, is now completed on the southeast side by a 22 m high body of the production area, situated in a rectangular form facing northeast and southeast. In the corner of this "active zone," a large terrace runs over the lower floor. Large glassed areas of the terrace open views of the city center and green gardens. They are divided by a 40 m high "vehicle cylinder," a section for vehicle dispatch, a customer "lounge," and a small administration wing. Access to the terrace and the "Experience Zone" and potential exit for completed vehicles is created by a light bridge over artificial water bodies. Prefabricated automotive parts are delivered to the underground yard in the southeast part of the production area.

In the "Experience Zone," the external single-shell glass wall is made of standard Schüco-FW50+ construction, a modular structure with insulating glazing. The load-bearing structure consists of steel pipes. In the "Manufacturing Area," the outer layer of the double facade is again made based on standard Schüco modular construction on massive flat steel profiles without a thermal bridge, suspended on steel arms anchored to the ceiling slab. The inner shell, which thermally separates the exterior space from the "Active Zone," is made of special Schüco profiles with insulating glazing. These profiles are secured with prestressed cables of stainless steel to take up vertical and horizontal forces. This solution allows the external and internal shells to be constructed with minimal static cross-section, making the structure appear very elegant and delicate.

The manufacturing area is fitted in the southeastern and southwestern corner with a double facade due to the need for temperature regulation depending on external climatic conditions. The overall value of the heat transfer coefficient is k=1.2, and the level of energy transfer when fully utilizing the awning slats reaches a value of 0.11.

Press release from Schüco International KG, Bielefeld

The text by Karla Doležela (Berlin Notebook, Architect 10/2002, pp. 68-70) prompted me to write an article about Prof. Henn, where he was necessarily overshadowed in comparison to Lord Foster. Prof. Dr. Günther Henn is, however, the head of the Institute of Industrial Building at the Technical University in Dresden. He owns a successful architectural office in Berlin and Munich. I had the opportunity to attend his lectures, where he willingly and engagingly shared his experiences. His work is encapsulated in operational schemes and graphs of industrial buildings, yet even in this position, he manages to innovate, come up with remarkable ideas, and sell them with his self-assured demeanor.

Petr Šmídek 01|2003

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment