Expansion of the INTEMAC Center

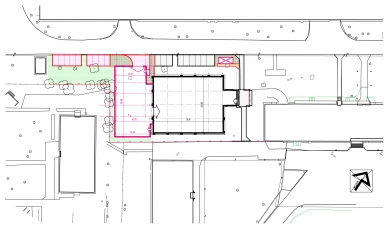

The INTEMAC Center is located in the Kuřim Industrial Zone. The area of the center in question is situated along Blanenská Street, which serves as a boundary between the original extensive premises of the engineering company TOS Kuřim and the new part of the zone. The existing part of the center is a reconstructed building from 2013 (by the same author), to which the presented implementation, the Expansion of the INTEMAC Center, is connected. It is an innovation and science-technical park designed for the development and implementation of modern technologies in engineering production. The project was realized by the South Moravian Region in collaboration with JIC, an association of legal entities in partnership with the Brno University of Technology and significant engineering companies.

The overall urban planning solution respects the existing building as a solitary structure, to which the new building connects at a necessary distance. The intention of the architectural design was to meet an unusual requirement for a combination of operations. Engineering laboratories modeling real manufacturing processes are concentrated on the following support facilities, with the possibility of presentations for a larger number of clients and visitors. Technical expression means are emphasized, additionally integrating a multitude of technical media in a small space. The innovative character of the connecting spaces was a determining motive for the realization of the interior. The artistic design works with motifs of production and technical activity. At the same time, the spaces are variably conceived for demanding presentations. The exterior of the building is an elemental cube. An individual production and arrangement of white concrete slab cladding was realized. The extension is a complement and simultaneously a contrast to the existing building, deliberately expressing a shift in time and technologies.

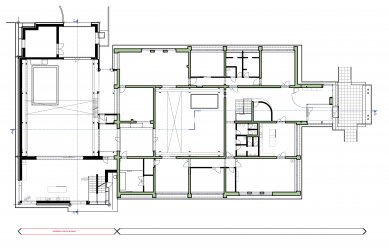

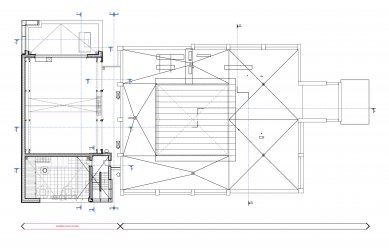

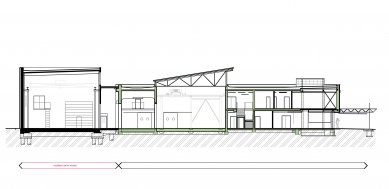

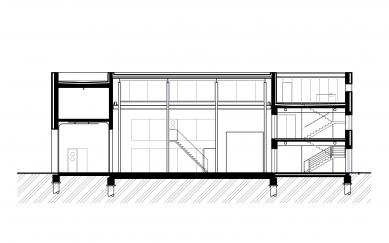

The core of the building is the main laboratory, which includes a bridge crane and a cast-iron clamping plate for precise measurements and testing. The hall space is naturally lit by a strip window from the northeast and further through glass walls towards the administrative part and into the neck with a gallery. Workshop rooms have direct visual contact with the laboratory from two sides of the floor plan.

On the second floor, there is a presentation room again with a view into the main laboratory. A new connection to the existing building was also created here. The connecting neck between the original building and the new building made maximum use of the confined conditions of the site. Despite the necessity of designing a gap due to the foundation of a heavy hall with an extreme floor, the offered gap was successfully utilized for connecting workshops and offices on both floors of the neck. Above the entrance, there is also a second floor at two levels. The space here includes an extensive machinery room for air conditioning and other equipment.

The third floor features a roof terrace and a stairwell extension. The space is designed as a relaxation area. The support facilities of the new building are located in the existing building, which includes locker rooms, toilets, another laboratory, offices, and a testing room.

Due to heat accumulation, masonry thermal insulation perimeter walls with insulation under the ventilated cladding were designed. The connecting neck has a lightweight independent steel structure. The monolithic reinforced concrete structure, especially for the ceilings, is present in the machinery room above the passage and in the administrative part with the staircase on the opposite side. The floor surfaces of the administrative part consist of poured screeds.

The main laboratory space serves for very precise machining and measurement, with increased demands on internal environment parameters, particularly long-term stability of the spatial temperature.

The operational conditions of the building are ensured by a sophisticated solution for air conditioning, ventilation, and recovery. Furthermore, an air/water heat pump and a solar thermal system are used. The facility is equipped with an RTLS – Real-time locating system.

The overall urban planning solution respects the existing building as a solitary structure, to which the new building connects at a necessary distance. The intention of the architectural design was to meet an unusual requirement for a combination of operations. Engineering laboratories modeling real manufacturing processes are concentrated on the following support facilities, with the possibility of presentations for a larger number of clients and visitors. Technical expression means are emphasized, additionally integrating a multitude of technical media in a small space. The innovative character of the connecting spaces was a determining motive for the realization of the interior. The artistic design works with motifs of production and technical activity. At the same time, the spaces are variably conceived for demanding presentations. The exterior of the building is an elemental cube. An individual production and arrangement of white concrete slab cladding was realized. The extension is a complement and simultaneously a contrast to the existing building, deliberately expressing a shift in time and technologies.

The core of the building is the main laboratory, which includes a bridge crane and a cast-iron clamping plate for precise measurements and testing. The hall space is naturally lit by a strip window from the northeast and further through glass walls towards the administrative part and into the neck with a gallery. Workshop rooms have direct visual contact with the laboratory from two sides of the floor plan.

On the second floor, there is a presentation room again with a view into the main laboratory. A new connection to the existing building was also created here. The connecting neck between the original building and the new building made maximum use of the confined conditions of the site. Despite the necessity of designing a gap due to the foundation of a heavy hall with an extreme floor, the offered gap was successfully utilized for connecting workshops and offices on both floors of the neck. Above the entrance, there is also a second floor at two levels. The space here includes an extensive machinery room for air conditioning and other equipment.

The third floor features a roof terrace and a stairwell extension. The space is designed as a relaxation area. The support facilities of the new building are located in the existing building, which includes locker rooms, toilets, another laboratory, offices, and a testing room.

Due to heat accumulation, masonry thermal insulation perimeter walls with insulation under the ventilated cladding were designed. The connecting neck has a lightweight independent steel structure. The monolithic reinforced concrete structure, especially for the ceilings, is present in the machinery room above the passage and in the administrative part with the staircase on the opposite side. The floor surfaces of the administrative part consist of poured screeds.

The main laboratory space serves for very precise machining and measurement, with increased demands on internal environment parameters, particularly long-term stability of the spatial temperature.

The operational conditions of the building are ensured by a sophisticated solution for air conditioning, ventilation, and recovery. Furthermore, an air/water heat pump and a solar thermal system are used. The facility is equipped with an RTLS – Real-time locating system.

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment