Bridge over the Wild Orlice River in Žamberk

Unique arched footbridge made of UHPC (ultra-high performance concrete) with an embedded steel structure for the decking and a baroque statue of St. John of Nepomuk.

On the site of the new footbridge, there was a classic arched concrete footbridge from the first half of the last century. The supporting structure consisted of a pair of concrete arches, each 350 mm thick. The footbridge was part of the city's panorama and was loved by locals. Unfortunately, the original structure was in such poor condition that it had to be replaced with a new one.

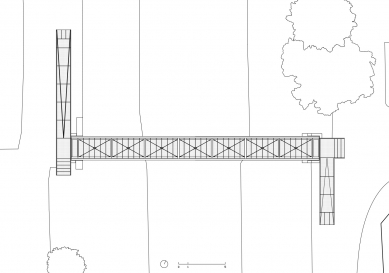

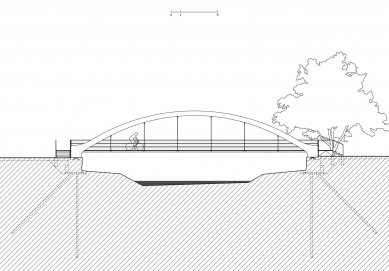

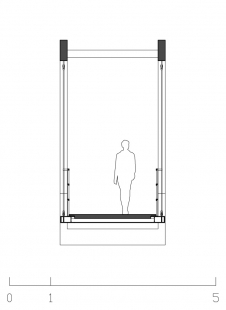

We came up with the concept of preserving the exact shape of the silhouette of the original concrete arch and casting the arches from UHPC. The resulting thickness of the arch construction is 175 mm, which is half that of the original concrete and appears very light. The silhouette of the original bridge remains preserved in the city's panorama, but in detail, it is a contemporary construction. The charm of this building lies in its shape referencing the original footbridge, using modern UHPC material that allowed for the creation of arches that are maximally slender and durable. This is the world's first UHPC structure with an upper arch. Between the arches, a delicate hot-dip galvanized steel structure of the decking is suspended. The passing width of the footbridge is 2.2 m. The span of the footbridge is 25.48 m.

The architectural solution includes the relocation of the postponed baroque stone statue of John of Nepomuk to the forecourt of the footbridge in accordance with iconographic tradition.

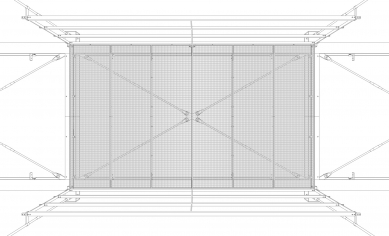

The supporting structure can be defined as an arch bridge structure with a tie and a suspended lower decking. The arches of the bridge made from UHPC are stabilized with steel struts. The grating decking, serving as the arch tie, is made of steel and is suspended by rod hangers to the arch structure. At the base of the arch, the steel decking is connected to the arch with a pin joint. The arch construction is made as a prefabricate with a mounting joint at the top.

Thus, precise halves of the pair of arched spans were produced. The mounting joint at the top of the arch was cast in-situ with the reinforcement intertwined using brackets. The prefabricates were cast in the "on the side" position, with the surface in contact with the formwork forming the external surface of the bridge.

The decking structure consists of longitudinal and transverse beams made from HEA 160 profiles, which together form seven spans. Each of the spans is diagonally braced with four ties and a central rosette. The decking is composed of grating panels. On the inner side of the decking's longitudinal element, there is a strip with LED lights for illuminating the decking. The railing consists of a stainless steel mesh.

On the site of the new footbridge, there was a classic arched concrete footbridge from the first half of the last century. The supporting structure consisted of a pair of concrete arches, each 350 mm thick. The footbridge was part of the city's panorama and was loved by locals. Unfortunately, the original structure was in such poor condition that it had to be replaced with a new one.

We came up with the concept of preserving the exact shape of the silhouette of the original concrete arch and casting the arches from UHPC. The resulting thickness of the arch construction is 175 mm, which is half that of the original concrete and appears very light. The silhouette of the original bridge remains preserved in the city's panorama, but in detail, it is a contemporary construction. The charm of this building lies in its shape referencing the original footbridge, using modern UHPC material that allowed for the creation of arches that are maximally slender and durable. This is the world's first UHPC structure with an upper arch. Between the arches, a delicate hot-dip galvanized steel structure of the decking is suspended. The passing width of the footbridge is 2.2 m. The span of the footbridge is 25.48 m.

The architectural solution includes the relocation of the postponed baroque stone statue of John of Nepomuk to the forecourt of the footbridge in accordance with iconographic tradition.

The supporting structure can be defined as an arch bridge structure with a tie and a suspended lower decking. The arches of the bridge made from UHPC are stabilized with steel struts. The grating decking, serving as the arch tie, is made of steel and is suspended by rod hangers to the arch structure. At the base of the arch, the steel decking is connected to the arch with a pin joint. The arch construction is made as a prefabricate with a mounting joint at the top.

Thus, precise halves of the pair of arched spans were produced. The mounting joint at the top of the arch was cast in-situ with the reinforcement intertwined using brackets. The prefabricates were cast in the "on the side" position, with the surface in contact with the formwork forming the external surface of the bridge.

The decking structure consists of longitudinal and transverse beams made from HEA 160 profiles, which together form seven spans. Each of the spans is diagonally braced with four ties and a central rosette. The decking is composed of grating panels. On the inner side of the decking's longitudinal element, there is a strip with LED lights for illuminating the decking. The railing consists of a stainless steel mesh.

author's report

The English translation is powered by AI tool. Switch to Czech to view the original text source.

1 comment

add comment

Subject

Author

Date

Gratulace!

Mirko Baum

10.04.25 10:44

show all comments