Manufacturing site LIFOCOLOR

Investor

LIFOCOLOR Brno is engaged in the production and development of multifunctional concentrates and technical compounds for the plastics industry. It is a subsidiary of a global manufacturer. The investor decided to relocate from the existing premises, which were no longer adequate for its capacities and could not be further expanded.

The investor’s brief called for a new facility that would meet the increasing capacity requirements for the company’s further development with a 30-year outlook. The company is very specific and unique in its focus both in the Czech and European markets. Therefore, the result was to be a custom-designed facility that would combine mutually closely linked functions into one building - production, storage, laboratories, and administration. The investor focused not only on the technological part of the company but also decided to invest increased funds in the architectural and aesthetic demands of the facility in order to present the company to customers and partners. Last but not least, to create a pleasant working environment for its employees at all levels of the company.

Location of the building

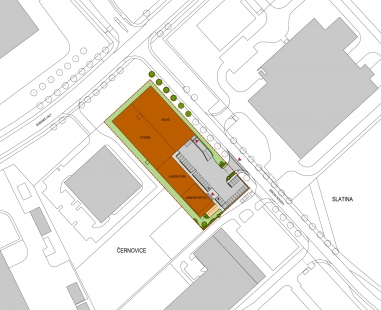

The construction of the Lifocolor production complex is integrated into the existing development of manufacturing facilities in the Brno industrial zone - Černovická terasa, in the cadastral area of Černovice. The complex is situated on flat land at the intersection of Ericha Roučky and Švédských valů streets. The entrance to the complex is from Ericha Roučky street.

Architectural solution

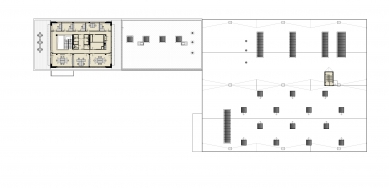

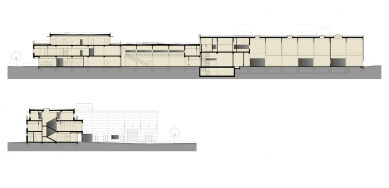

The entire L-shaped building is composed of two basic masses - the production and storage halls, to which the mass of the administrative part and laboratories is attached. This division of masses according to functional use is deliberately reflected in the height arrangement of the masses and the material solution of the exterior. The façade of the hall and storage is uniformly cladded in facade panels measuring 6x1m (light gray). The mass of the administration and laboratories is uniformly cladded in façade cassettes measuring 3x0.5m (anthracite gray). The emphasis on the main entrance to the building is highlighted by the mass of the bay window at the level of the 2nd floor, which is clad in corrugated metal (red). Corrugated metal is also used on the set-back parts of the administration on the 3rd floor (light gray). The administrative part is glazed with strips of windows with sills, supplemented in parts by fully glazed façades of the entrance area, dining room, conference room, and entrances to the terrace on the 3rd floor. The hall space of the laboratories is illuminated by a prominent fully glazed façade, which also creates an optical separation from the mass of production and storage. The space is additionally illuminated by roof skylights. The production hall has glazed sections in the office area with strips of windows with sills. The main lighting of the production and storage areas is resolved by roof skylights. The façades of the hall exposed to the main communications serve for placing the investor's logo and advertising surfaces. Other protruding structures on the façade - awnings and a canopy over the delivery ramp are color-coordinated with the color scheme of the façades.

Outdoor areas are complemented by relaxation spaces in the form of terraces on the 1st and 3rd floors with an adjoining visual vegetation roof over the laboratory. Greenery throughout the complex is then addressed with landscaping (lawns, planting of trees, shrubs, perennials, and ornamental grasses).

Operational solution

Operational activity is expected to operate in the future in a three-shift operational regime. The maximum projected capacity is approximately 70 employees. The administrative section is designed in the southeast part of the plot, where there is also a quiet zone for employees.

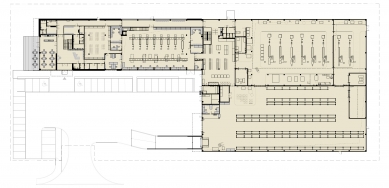

From the administrative section, access to the production hall and then to the storage hall is provided via a corridor along the laboratories. The administrative part is intentionally set back from the production and storage section so that it is not in direct contact with the production part of the facility. For the same reason, it is set back from the main street line.

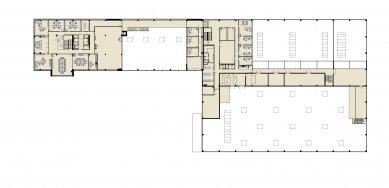

The administrative part allows direct linkage to the laboratory section, where there is access for client presentations. Within the administrative section, there is also staff support, locker rooms with showers for laboratory staff, and a dining room for all employees. Offices and conference rooms are located on the 2nd floor. On the 3rd floor, there is access to two terraces oriented south-north. The northern terrace is designed with a view of the green roof over the laboratory. Between the administrative section and the laboratories is located a two-story fund - a sample storage for the company.

The production section is architecturally divided on the 1st floor into areas for mixing and preparation, production areas, and cleaning areas. The mixing room is located in direct connection to the laboratory. In direct connection to the mixing room, there is a vertical communication corridor - a staircase that allows access to the technical room in the basement (sewage treatment plant, part of the technological cooling) and also to the 2nd floor, where the offices of administrative production staff and locker rooms for production employees are located. On the 2nd floor of the production section, the technical support of the facility is arranged - boiler room, air handling unit machine room, low voltage distribution. In connection with the technological background, there is a staircase with access to the roof, where platforms for outdoor units are located. The storage section is directly connected to the production areas and the mixing room. The storage includes a separate room for flammable materials.

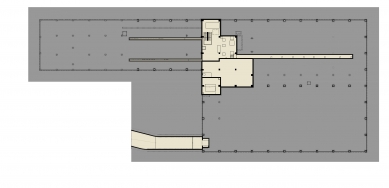

The pump station and sprinkler tank are situated in the basement. Access to the pump station is from the outside, from the courtyard space of the complex.

Interior

The interior was mainly developed for the administrative part - the design of hallways and the main staircase with adjoining transparently open spaces of the reception, dining room, conference rooms, up to closed spaces of individual offices and technical rooms. The entire concept used in the administrative part was then locally transferred into other parts of the building - generously open spaces of laboratories with a gallery and further into the production and storage section.

As this is a company working with an almost unlimited color palette, which is reflected in the interior through the final product, emphasis was placed on clarity and cleanliness of the spaces in the design. Predominantly light colors are used in the interior, accented with tones of red and gray, partially green and yellow. Natural linoleum, colored wall stucco in contrast with white and gray painting, laminated boards, glass, and metal were utilized. In the common areas of the administrative part, a play with lines of light is created. Above the main staircase, there is an open atrium topped with a set of suspended linear lights.

The company's final product is a granular bulk material, which is colored in various shades. The complex development of individual shades occurs in the laboratory. Therefore, the laboratories are well lit and the surfaces are tuned to light tones. The color play is fulfilled here by the products themselves and technological elements like powdered colors in transparent containers arranged on shelves, granules that are cut from colored hanging strands. The granulate was also used in the interior as a filling for the conference table.

The color plates used in the development of color shades are also contained in the company logo. This element was graphically used in an abstract form for the prints on the glazed walls. In colored plexiglass execution, it creates a view between the entrance and the dining room and transitions into a volumetric element on the wall. The logo motif was reflected, for example, in the design of room signs and wall clocks.

The simple design of the furniture was tuned for the administrative part in white color, in the remaining spaces in gray color. The white and gray simplicity of the volumes was enlivened with colorful upholstery of chairs and sofas or room dividers.

The interior is enlivened by glazed showcases with the final colored products of the company's clients.

Technical solution

The foundation is designed as a deep foundation on piles. The technological pits and channels are designed as reinforced concrete monolithic constructions.

The vertical load-bearing structures of the entire building are made of prefabricated reinforced concrete columns. The cladding is designed with regard to the different functions of the individual parts of the building. In the administrative part, sandwich constructions of the external walls with façade cassettes are proposed. In the storage and production part, insulating façade panels with a polyurethane core are proposed.

In the administrative and laboratory sections, the ceiling load-bearing structure consists of a system of prefabricated beams with a rectangular cross-section with consoles for laying prestressed ceiling panels, while in the production and storage section, the load-bearing structure of the roof consists of prestressed reinforced concrete pitched trusses with corrugated metal sheeting.

In the administrative part, a dry construction system is used, with drywall partitions with inserted sound insulation made of mineral wool. The partitions between the storage and production sections, and technical and production-related rooms will be constructed from aerated concrete blocks.

Individual floors are vertically connected by several staircases (prefabricated reinforced concrete and steel with a walking grid). A small freight elevator is designed for transporting packaged samples from the laboratory to the sample storage.

LIFOCOLOR Brno is engaged in the production and development of multifunctional concentrates and technical compounds for the plastics industry. It is a subsidiary of a global manufacturer. The investor decided to relocate from the existing premises, which were no longer adequate for its capacities and could not be further expanded.

The investor’s brief called for a new facility that would meet the increasing capacity requirements for the company’s further development with a 30-year outlook. The company is very specific and unique in its focus both in the Czech and European markets. Therefore, the result was to be a custom-designed facility that would combine mutually closely linked functions into one building - production, storage, laboratories, and administration. The investor focused not only on the technological part of the company but also decided to invest increased funds in the architectural and aesthetic demands of the facility in order to present the company to customers and partners. Last but not least, to create a pleasant working environment for its employees at all levels of the company.

Location of the building

The construction of the Lifocolor production complex is integrated into the existing development of manufacturing facilities in the Brno industrial zone - Černovická terasa, in the cadastral area of Černovice. The complex is situated on flat land at the intersection of Ericha Roučky and Švédských valů streets. The entrance to the complex is from Ericha Roučky street.

Architectural solution

The entire L-shaped building is composed of two basic masses - the production and storage halls, to which the mass of the administrative part and laboratories is attached. This division of masses according to functional use is deliberately reflected in the height arrangement of the masses and the material solution of the exterior. The façade of the hall and storage is uniformly cladded in facade panels measuring 6x1m (light gray). The mass of the administration and laboratories is uniformly cladded in façade cassettes measuring 3x0.5m (anthracite gray). The emphasis on the main entrance to the building is highlighted by the mass of the bay window at the level of the 2nd floor, which is clad in corrugated metal (red). Corrugated metal is also used on the set-back parts of the administration on the 3rd floor (light gray). The administrative part is glazed with strips of windows with sills, supplemented in parts by fully glazed façades of the entrance area, dining room, conference room, and entrances to the terrace on the 3rd floor. The hall space of the laboratories is illuminated by a prominent fully glazed façade, which also creates an optical separation from the mass of production and storage. The space is additionally illuminated by roof skylights. The production hall has glazed sections in the office area with strips of windows with sills. The main lighting of the production and storage areas is resolved by roof skylights. The façades of the hall exposed to the main communications serve for placing the investor's logo and advertising surfaces. Other protruding structures on the façade - awnings and a canopy over the delivery ramp are color-coordinated with the color scheme of the façades.

Outdoor areas are complemented by relaxation spaces in the form of terraces on the 1st and 3rd floors with an adjoining visual vegetation roof over the laboratory. Greenery throughout the complex is then addressed with landscaping (lawns, planting of trees, shrubs, perennials, and ornamental grasses).

Operational solution

Operational activity is expected to operate in the future in a three-shift operational regime. The maximum projected capacity is approximately 70 employees. The administrative section is designed in the southeast part of the plot, where there is also a quiet zone for employees.

From the administrative section, access to the production hall and then to the storage hall is provided via a corridor along the laboratories. The administrative part is intentionally set back from the production and storage section so that it is not in direct contact with the production part of the facility. For the same reason, it is set back from the main street line.

The administrative part allows direct linkage to the laboratory section, where there is access for client presentations. Within the administrative section, there is also staff support, locker rooms with showers for laboratory staff, and a dining room for all employees. Offices and conference rooms are located on the 2nd floor. On the 3rd floor, there is access to two terraces oriented south-north. The northern terrace is designed with a view of the green roof over the laboratory. Between the administrative section and the laboratories is located a two-story fund - a sample storage for the company.

The production section is architecturally divided on the 1st floor into areas for mixing and preparation, production areas, and cleaning areas. The mixing room is located in direct connection to the laboratory. In direct connection to the mixing room, there is a vertical communication corridor - a staircase that allows access to the technical room in the basement (sewage treatment plant, part of the technological cooling) and also to the 2nd floor, where the offices of administrative production staff and locker rooms for production employees are located. On the 2nd floor of the production section, the technical support of the facility is arranged - boiler room, air handling unit machine room, low voltage distribution. In connection with the technological background, there is a staircase with access to the roof, where platforms for outdoor units are located. The storage section is directly connected to the production areas and the mixing room. The storage includes a separate room for flammable materials.

The pump station and sprinkler tank are situated in the basement. Access to the pump station is from the outside, from the courtyard space of the complex.

Interior

The interior was mainly developed for the administrative part - the design of hallways and the main staircase with adjoining transparently open spaces of the reception, dining room, conference rooms, up to closed spaces of individual offices and technical rooms. The entire concept used in the administrative part was then locally transferred into other parts of the building - generously open spaces of laboratories with a gallery and further into the production and storage section.

As this is a company working with an almost unlimited color palette, which is reflected in the interior through the final product, emphasis was placed on clarity and cleanliness of the spaces in the design. Predominantly light colors are used in the interior, accented with tones of red and gray, partially green and yellow. Natural linoleum, colored wall stucco in contrast with white and gray painting, laminated boards, glass, and metal were utilized. In the common areas of the administrative part, a play with lines of light is created. Above the main staircase, there is an open atrium topped with a set of suspended linear lights.

The company's final product is a granular bulk material, which is colored in various shades. The complex development of individual shades occurs in the laboratory. Therefore, the laboratories are well lit and the surfaces are tuned to light tones. The color play is fulfilled here by the products themselves and technological elements like powdered colors in transparent containers arranged on shelves, granules that are cut from colored hanging strands. The granulate was also used in the interior as a filling for the conference table.

The color plates used in the development of color shades are also contained in the company logo. This element was graphically used in an abstract form for the prints on the glazed walls. In colored plexiglass execution, it creates a view between the entrance and the dining room and transitions into a volumetric element on the wall. The logo motif was reflected, for example, in the design of room signs and wall clocks.

The simple design of the furniture was tuned for the administrative part in white color, in the remaining spaces in gray color. The white and gray simplicity of the volumes was enlivened with colorful upholstery of chairs and sofas or room dividers.

The interior is enlivened by glazed showcases with the final colored products of the company's clients.

Technical solution

The foundation is designed as a deep foundation on piles. The technological pits and channels are designed as reinforced concrete monolithic constructions.

The vertical load-bearing structures of the entire building are made of prefabricated reinforced concrete columns. The cladding is designed with regard to the different functions of the individual parts of the building. In the administrative part, sandwich constructions of the external walls with façade cassettes are proposed. In the storage and production part, insulating façade panels with a polyurethane core are proposed.

In the administrative and laboratory sections, the ceiling load-bearing structure consists of a system of prefabricated beams with a rectangular cross-section with consoles for laying prestressed ceiling panels, while in the production and storage section, the load-bearing structure of the roof consists of prestressed reinforced concrete pitched trusses with corrugated metal sheeting.

In the administrative part, a dry construction system is used, with drywall partitions with inserted sound insulation made of mineral wool. The partitions between the storage and production sections, and technical and production-related rooms will be constructed from aerated concrete blocks.

Individual floors are vertically connected by several staircases (prefabricated reinforced concrete and steel with a walking grid). A small freight elevator is designed for transporting packaged samples from the laboratory to the sample storage.

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment