Ytong conquered the Chinese EXPO

From May to October, the Chinese metropolis of Shanghai will host the most significant international construction fair, EXPO. The motto of the fair - Better City - Better Life - responds to the demand for sustainable urban construction. This year's EXPO was also marked by high demands on the design of individual exhibition complexes. The company Xella, the manufacturer of aerated concrete Ytong, was listed among the key suppliers for the construction of fair pavilions. It has thus proven that it is justifiably competing for a position as a leader in energy-efficient building.

“We all know that the most important market today is the Chinese one. It is the only one that has not yet felt the crisis and, thanks to sufficient financial reserves, it keeps economic giants like the United States in check. A successful entry into the Chinese market is therefore one of the fundamental prerequisites for a successful international trade policy. However, after years of uncontrolled boom, China is beginning to realize the necessity of sustainable construction and is starting to follow Western trends. This will largely be reflected in the upcoming Expo 2010. For the Xella group, being part of the construction of the exhibition complexes is an honor and a significant recognition of the ’sustainability’ of our building materials and their production,” comments the success of the international company Xella, Ivana Havlíčková, marketing director of the Czech branch. The Ytong material was used in the construction of the three most important buildings of the entire exhibition - World Expo Center, Performance Center, and Expo Theme Pavilion.

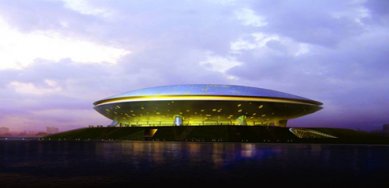

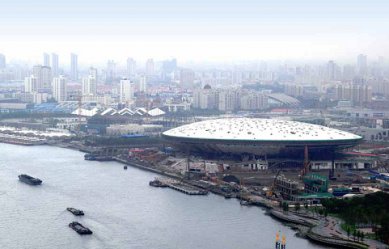

The Performance Centre, a structure shaped like a flying saucer with a capacity of 18 thousand seated visitors, appears particularly impressive. Its construction used 10,000 m³ of Ytong. The largest amount, 10,350 m³ of Ytong material, was utilized in the construction of the “Theme Pavilion,” which is meant to represent the theme of Expo 2010 “Better City - Better Life.”

All three buildings will find use even after the exhibition. In all cases, similar reasons determined the use of Ytong material. Besides short-term benefits, which include the lightness of the material, sufficient strength, load-bearing capacity, and precise construction, Ytong also provides versatile advantages from a long-term perspective. Investors particularly appreciate the excellent thermal insulation properties, fire resistance, and adequate sound insulation of the material. One of the decisive arguments was also reliable delivery and fast construction, as the implementation of demanding exhibition projects understandably could not do without the necessity of meeting “tight” deadlines.

The local production plant provided Ytong material not only for the international pavilions but also for the Swedish and Moroccan pavilions, as well as for the French regional pavilion Rhône-Alpes. This complex is an exemplary example of energy-efficient construction: the operation of conference spaces is generally very energy-intensive, yet the building complies with strict European standards for low-energy building regulation. “We had very high demands for the execution of the building. Our goal was to ensure the best materials and technologies. Ytong is the only massive walling material on the market that has such excellent thermal insulation properties,” justifies the use of Ytong blocks, the representative director of the pavilion, Jean-Maurice Hebrard. The building is constructed from blocks with a thermal conductivity coefficient of 0.09 W/m²·K, which is unmatched in Chinese standards. This value attracted unprecedented attention already when it was introduced to the market long before the preparations for Expo 2010.

“Expo provides a vision of future urban life. A key element is modern architecture for sustainable buildings. We are very proud to be a part of it,” adds Jan Buck Emden, CEO of Ytong Xella Group, in conclusion.

YTONG is primarily used for the construction of apartment and family houses due to its unique thermal insulation parameters, ensuring year-round thermal and moisture comfort. Its environmentally friendly and energy-efficient production, combined with the minimal energy consumption of buildings, positions YTONG aerated concrete among the most environmentally friendly building materials available today. High precision, low weight, speed, and simple masonry technology also make it suitable for the renovation of all types of buildings. White YTONG aerated concrete is exclusively produced from high-quality natural raw materials, such as silica sand, lime, cement, and water. Therefore, it is ideal for buildings designed for long-term human habitation, including spaces with enhanced hygiene requirements.

The production of YTONG aerated concrete is ensured in the Czech Republic by Xella CZ. In three production plants, approximately 350 employees produce about 1,000,000 m³ of this precise building material annually. In addition to the YTONG aerated concrete building system, the company also offers a comprehensive range of lime-sand blocks SILKA, which stand out for their exceptional load-bearing capacity and extreme sound insulation. The combination of YTONG and Silka materials creates optimal building solutions for both regular and special projects in civil, residential, and industrial construction.

More information about Xella and the product range can be found at www.xella.cz and www.ytong.cz.

|

“We all know that the most important market today is the Chinese one. It is the only one that has not yet felt the crisis and, thanks to sufficient financial reserves, it keeps economic giants like the United States in check. A successful entry into the Chinese market is therefore one of the fundamental prerequisites for a successful international trade policy. However, after years of uncontrolled boom, China is beginning to realize the necessity of sustainable construction and is starting to follow Western trends. This will largely be reflected in the upcoming Expo 2010. For the Xella group, being part of the construction of the exhibition complexes is an honor and a significant recognition of the ’sustainability’ of our building materials and their production,” comments the success of the international company Xella, Ivana Havlíčková, marketing director of the Czech branch. The Ytong material was used in the construction of the three most important buildings of the entire exhibition - World Expo Center, Performance Center, and Expo Theme Pavilion.

The Performance Centre, a structure shaped like a flying saucer with a capacity of 18 thousand seated visitors, appears particularly impressive. Its construction used 10,000 m³ of Ytong. The largest amount, 10,350 m³ of Ytong material, was utilized in the construction of the “Theme Pavilion,” which is meant to represent the theme of Expo 2010 “Better City - Better Life.”

All three buildings will find use even after the exhibition. In all cases, similar reasons determined the use of Ytong material. Besides short-term benefits, which include the lightness of the material, sufficient strength, load-bearing capacity, and precise construction, Ytong also provides versatile advantages from a long-term perspective. Investors particularly appreciate the excellent thermal insulation properties, fire resistance, and adequate sound insulation of the material. One of the decisive arguments was also reliable delivery and fast construction, as the implementation of demanding exhibition projects understandably could not do without the necessity of meeting “tight” deadlines.

The local production plant provided Ytong material not only for the international pavilions but also for the Swedish and Moroccan pavilions, as well as for the French regional pavilion Rhône-Alpes. This complex is an exemplary example of energy-efficient construction: the operation of conference spaces is generally very energy-intensive, yet the building complies with strict European standards for low-energy building regulation. “We had very high demands for the execution of the building. Our goal was to ensure the best materials and technologies. Ytong is the only massive walling material on the market that has such excellent thermal insulation properties,” justifies the use of Ytong blocks, the representative director of the pavilion, Jean-Maurice Hebrard. The building is constructed from blocks with a thermal conductivity coefficient of 0.09 W/m²·K, which is unmatched in Chinese standards. This value attracted unprecedented attention already when it was introduced to the market long before the preparations for Expo 2010.

“Expo provides a vision of future urban life. A key element is modern architecture for sustainable buildings. We are very proud to be a part of it,” adds Jan Buck Emden, CEO of Ytong Xella Group, in conclusion.

YTONG is primarily used for the construction of apartment and family houses due to its unique thermal insulation parameters, ensuring year-round thermal and moisture comfort. Its environmentally friendly and energy-efficient production, combined with the minimal energy consumption of buildings, positions YTONG aerated concrete among the most environmentally friendly building materials available today. High precision, low weight, speed, and simple masonry technology also make it suitable for the renovation of all types of buildings. White YTONG aerated concrete is exclusively produced from high-quality natural raw materials, such as silica sand, lime, cement, and water. Therefore, it is ideal for buildings designed for long-term human habitation, including spaces with enhanced hygiene requirements.

The production of YTONG aerated concrete is ensured in the Czech Republic by Xella CZ. In three production plants, approximately 350 employees produce about 1,000,000 m³ of this precise building material annually. In addition to the YTONG aerated concrete building system, the company also offers a comprehensive range of lime-sand blocks SILKA, which stand out for their exceptional load-bearing capacity and extreme sound insulation. The combination of YTONG and Silka materials creates optimal building solutions for both regular and special projects in civil, residential, and industrial construction.

More information about Xella and the product range can be found at www.xella.cz and www.ytong.cz.

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment