The roofing of the western atrium of building D of the Faculty of Civil Engineering of Czech Technical University in Prague

<hala>for teaching <atelier>workshop</atelier> creation</hala>

AREA OF TEACHING SPACES: 794 m²

AREA OF BACKGROUND AND STORAGE: 50 m²

AREA OF COMMUNICATIONS: 199 m³

Original project and building before reconstruction

The urban space of Prague's Dejvice around today's Victory Square has undergone (and will probably continue to undergo) a turbulent development, and many projects and competition proposals, both professional and student, have been developed for the overall space or its partial segments. While the exposed focal point of the space is logically located at today's Victory Square, the construction project of Atrium D can be considered, on the contrary, a modest and partially hidden focal point of the Department of Architecture at the Faculty of Civil Engineering of CTU Prague.

The magnificent urban concept designed by Antonín Engel in the 1920s was partly built before World War II, but it was not completed in its original neoclassical spirit. At the end of the 1950s, the realization of another part along the main axis of the CTU campus began according to the winning proposal by František Čermák and Gustav Paul, and the buildings of today's Faculty of Civil Engineering and Faculty of Architecture were completed at the turn of the 1960s and 1970s. The project we designed, Atrium D, is located in the northwestern end section of the elongated and low Building D of the Faculty of Civil Engineering. The two-story, partially basement building is connected to the remaining buildings (the long part B, the tall part A) via connecting links through the entrance building C.

The current technical condition of the building corresponds to the time of its creation and the potential for its functionality for today’s teaching needs. Atrium D filled the space of the original farmyard, which served as access to associated testing halls, workshops, and laboratories, for storing materials and parking handling equipment. Beneath the asphalt surface, bulky reinforced concrete tanks for water and other materials needed for experiments in the neighboring halls were hidden. The austere glazed suspended facade with vertical aluminum slats mirrors the overall external impression of the entire building, which is unfortunately slightly gloomy after almost half a century of use and raises the question of how much it reflects the essence of the entire facility as a higher education institution focused on technical education, which should rather set an example in the area of building development.

Concept and Purpose of the Whole Reconstruction

The overall concept of the original building is probably now somewhat outdated for the purposes of a university, the capacity of the school is filled, and there is a lack of free space. Partial modifications and reconstructions are being realized, but the school lacks larger open spaces that could serve multiple purposes - for teaching, lectures, as well as for presenting new proposals and ideas, work, and relaxation. The twenty-first century is referred to as the information age (if it is not rather the "disinformation age," but that will only become clear with time), and the school should primarily serve as a platform for the open exchange of information, from which everyone can learn from the experiences of all others.

It was therefore a logical decision on the part of the Department of Architecture to utilize the farmyard, which was no longer fulfilling its original function 100%, to house a large multifunctional teaching space that would meet new demands. The original supply function of the courtyard was to be preserved at least in a limited form, which, however, could be combined with the new operation.

Atrium D is one of the possible ways to enrich the current teaching space of the school; unfortunately, the results of the school leadership's efforts are limited by the budget of Czech education, and thus the completed building represents only a fraction of what would be appropriate to realize in total for ensuring quality spaces for teaching.

Study versus Project

The task of the study was to develop a proposal for a program created by the Department of Architecture of the Faculty of Civil Engineering, which included an inner courtyard along with adjacent spaces, essentially covering the entire end section of Building D across both above-ground floors.

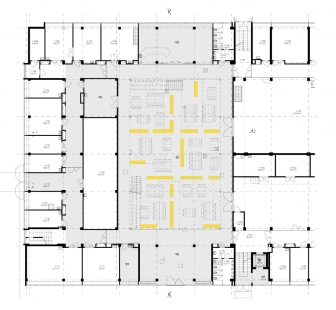

By roofing the entire courtyard, a large, open, almost industrial-looking hall is created - a factory for ideas, which is the leitmotif of the entire project. The free arrangement of workstations in the space respects the current needs of individual studios, allowing them to contract, expand, and integrate with other studios as the situation demands. Students do not shut themselves off with their mentors behind impenetrable walls. On the contrary, the opportunity to observe how ideas develop in other studios can be enriching for all.

This intent is the foundation of the overall concept of the reconstruction. The main emphasis was placed on the studios located both on the ground floor in the open hall space and on the southwest facade of the building for closeable studio rooms. The main two-story space is complemented by other operations necessary for the optimal functioning of the department.

Entrances to the atrium were positioned near the connecting bridge to Building "B" of the Faculty of Civil Engineering, and additionally, an alternative entrance directly from Kolejní Street was proposed at the location of the existing passage. This entrance, which was significantly architecturally designed, was intended to draw attention to the fact that something interesting was happening in this otherwise rather monotonous building. The entire reconstructed section was to satisfy the complete needs of students of architecture and create a compactly functioning whole.

However, this proposal was not realized in full extent due to operational and financial reasons, and the project already counted on significant limitations, with the scope of changes newly effectively defined by the outline of the original farmyard, in association with rooms on the 1st floor towards the southwest and northeast facades. Closed studio rooms, a computer room, and teachers' offices were removed from the program. A significant entry element was eliminated and replaced with a discreet barrier-free entry under the connecting link in the spirit of the ongoing door exchange throughout the faculty.

During the project's execution, many other minor or technological changes occurred; the most significant was probably the overall simplification of the air-conditioning provision of the space. The originally sophisticated air-conditioning and climate control system was replaced with a simpler and more economical design, relying more on natural ventilation and pre-cooling the space during the night hours in the summer months. Ultimately, the fact that students are on holiday during the hottest months of the year contributes to the feeling that this decision was correct.

Spatial Relationships

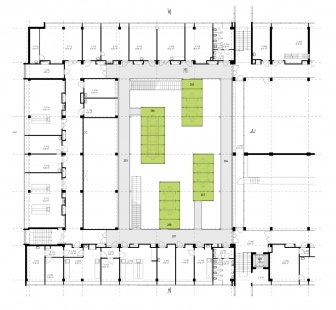

In the end, the realized space retained the most important aspect of the original concept, that open factory hall for ideas. The main entrance to the teaching space remained where Building D connects with Building C via a pedestrian bridge, either on the 1st floor directly into the studio spaces or to corridors and galleries on the 2nd floor, from where access is provided via suspended bridges to four hanging classrooms designated for teaching in smaller groups or consultations with a teacher. The open space on the 1st floor serves for any arrangement of six to eight studios, which are mutually separated by mobile furniture walls with lockable storage, allowing total space variability. All furnishings can be relatively easily relocated or rearranged so that new spaces or one large space are created that can be used for various purposes: exhibitions, lectures, conferences, state exams, social events. The adjacent longer walls are designed as exhibition areas for student work, while also serving an acoustic function. At the shorter sides, there are adjoining spaces - a respirium for relaxation and meeting, and on the other side, a technically equipped model-making room.

Daylight is provided through longitudinal skylights and glazed sides of the elevated roof structure. As protection against sunlight, external blinds are installed on the side glazing, and the polycarbonate closure of the skylights at the level of the ceiling provides the space with diffuse light.

Construction Solution, Technologies, and Materials Used

The load-bearing structure of the original building is a prefabricated reinforced concrete skeleton with a suspended facade and partitions predominantly made of ceramic masonry. The project envisaged the removal of the facade and moving layers of the inner courtyard and the installation of a new steel structure as independent as possible from the original structures.

The new steel structure consists of columns that are either founded on new base pads or on reinforced existing basement constructions. The columns carry connecting bridges on the 2nd floor, partially staircases, and primarily trussed girders forming the roof structure. Suspended from the roof are consultation boxes and also parts of staircases and bridges. The staircases are made of interconnected steel truss beams with sheet metal steps, which have anti-slip coatings. On the roof is a steel frame structure housing the ventilation machinery, clad in corrugated sheet metal that serves as an acoustic barrier.

In terms of design for materials and surface finishes of the interior, we adhered to the industrial and technical expression of the factory concept, aligning with the character of the adjacent halls. The foundation was rooted in simplicity and the naturalness of industrially appearing materials, without unnecessary surface treatments; the inner surfaces of ceilings and parts of walls are made of cement-bonded particleboards in a natural shade or galvanized expanded mesh that exposes the structure of the support profiles; the atrium is divided from neighboring rooms by copolymer walls or partitions with acoustic cladding from wood-fiber boards with textile wallpaper. The steel structure remained exposed and is a significant art component of the interior; the bridges leading to the suspended classrooms are also designed as visible steel constructions with perforated plates instead of traditional flooring. The character of the space is defined by four suspended classrooms formed by steel frames, clad with 22 mm thick special colored honeycomb polycarbonate sheets; the inner ceilings of these boxes are made of milky hollow polycarbonate to allow light to penetrate from the longitudinal skylights in the roof envelope. Fluorescent lights are incorporated into the cladding panels of the classroom structure, while other lights in the atrium are simply suspended in their "raw" visible form on troughs that distribute data and power cabling or in expanded mesh ceilings. All electrical wiring and air-conditioning are left exposed, thereby contributing to the overall design of the space. A new wire-reinforced concrete floor is implemented on the 1st floor, allowing for the movement of a three-ton cart for supplying the adjacent laboratories; on the 2nd floor, part of the floor is made of cement screed and part of studded rubber, while the consultation boxes have a floor made of glass panels.

Construction Implementation and Unforeseen Technological Issues

Since this was a reconstruction, we expected that the conditions for the construction would naturally be challenging. Especially since the construction took place under significant time pressure and that the construction documentation of the original project of the faculty, from which we had to work on the project, was not completely preserved and did not always correspond to the realities found directly during construction. A significant issue was the number of control and storage shafts located in the former courtyard space. Some were not depicted at all in the original drawing documentation and were hidden beneath loading layers, while for others, it was very difficult to ascertain the load-bearing capacity of their ceiling. Another problem was the replacement of the original freight elevator with a new passenger one, as the internal dimensions of the shaft did not match the expected dimensions, which posed certain challenges in the short timeframe needed to manufacture and prepare the elevator technology. In the removed facade cladding, asbestos was discovered, which complicated the technological aspect and prolonged construction time. The facade had to be secured from the inside and outside before dismantling to prevent contamination of the surrounding environment. Moreover, the entire construction was carried out while the school was fully operational and even in rooms that were still in use during construction. For example, in the room of the adjacent laboratory, a long-term geotechnical experiment requiring a stable thermal environment was ongoing, which could not be moved from this room, and we routed new ventilation through it while removing the asbestos-containing facade cladding. Due to this time-space collision, the original material solution of the load-bearing partition had to be replaced from masonry to a steel structure with drywall cladding to avoid wet construction processes.

We were disappointed by the technical problems with the cladding panels made of colored polycarbonate Bencore, intended for the walls of the suspended classrooms. Our initial idea that the panels would be attached to the steel structure using only high-strength double-sided adhesive tape (according to the manufacturer's static data, this solution should be fully sufficient) evaporated the moment the panels began to disintegrate after attaching the first pieces. According to the manufacturer, this was caused by the selected atypical color of the face panels made of plexiglass. The supplier of the sandwich panels re-glued them at their own expense, but trust in their proclaimed excellent static properties was lost, and the panels, which were originally meant to function as solid walls of the boxes, were instead secured with screws to ensure the glued connections. For safety reasons, the inner sides of these walls will also be equipped with handrail bars.

A minor challenge was resolving the surfaces of two steel staircase ramps in the atrium space. The trussed structure is clad in aluminum sheets painted in high-gloss black powder coating, which are also adhered with high-strength double-sided adhesive tape (with securing screws), but the problem arose with the metal steps, whose treads needed to exhibit sufficient and guaranteed anti-slip properties. After a long search, the supplier managed to find a manufacturer of anti-slip coatings for sheet metal, though we were surprised that it is a relatively unique product in its category.

Despite all the difficulties,

AREA OF BACKGROUND AND STORAGE: 50 m²

AREA OF COMMUNICATIONS: 199 m³

Original project and building before reconstruction

The urban space of Prague's Dejvice around today's Victory Square has undergone (and will probably continue to undergo) a turbulent development, and many projects and competition proposals, both professional and student, have been developed for the overall space or its partial segments. While the exposed focal point of the space is logically located at today's Victory Square, the construction project of Atrium D can be considered, on the contrary, a modest and partially hidden focal point of the Department of Architecture at the Faculty of Civil Engineering of CTU Prague.

The magnificent urban concept designed by Antonín Engel in the 1920s was partly built before World War II, but it was not completed in its original neoclassical spirit. At the end of the 1950s, the realization of another part along the main axis of the CTU campus began according to the winning proposal by František Čermák and Gustav Paul, and the buildings of today's Faculty of Civil Engineering and Faculty of Architecture were completed at the turn of the 1960s and 1970s. The project we designed, Atrium D, is located in the northwestern end section of the elongated and low Building D of the Faculty of Civil Engineering. The two-story, partially basement building is connected to the remaining buildings (the long part B, the tall part A) via connecting links through the entrance building C.

The current technical condition of the building corresponds to the time of its creation and the potential for its functionality for today’s teaching needs. Atrium D filled the space of the original farmyard, which served as access to associated testing halls, workshops, and laboratories, for storing materials and parking handling equipment. Beneath the asphalt surface, bulky reinforced concrete tanks for water and other materials needed for experiments in the neighboring halls were hidden. The austere glazed suspended facade with vertical aluminum slats mirrors the overall external impression of the entire building, which is unfortunately slightly gloomy after almost half a century of use and raises the question of how much it reflects the essence of the entire facility as a higher education institution focused on technical education, which should rather set an example in the area of building development.

Concept and Purpose of the Whole Reconstruction

The overall concept of the original building is probably now somewhat outdated for the purposes of a university, the capacity of the school is filled, and there is a lack of free space. Partial modifications and reconstructions are being realized, but the school lacks larger open spaces that could serve multiple purposes - for teaching, lectures, as well as for presenting new proposals and ideas, work, and relaxation. The twenty-first century is referred to as the information age (if it is not rather the "disinformation age," but that will only become clear with time), and the school should primarily serve as a platform for the open exchange of information, from which everyone can learn from the experiences of all others.

It was therefore a logical decision on the part of the Department of Architecture to utilize the farmyard, which was no longer fulfilling its original function 100%, to house a large multifunctional teaching space that would meet new demands. The original supply function of the courtyard was to be preserved at least in a limited form, which, however, could be combined with the new operation.

Atrium D is one of the possible ways to enrich the current teaching space of the school; unfortunately, the results of the school leadership's efforts are limited by the budget of Czech education, and thus the completed building represents only a fraction of what would be appropriate to realize in total for ensuring quality spaces for teaching.

Study versus Project

The task of the study was to develop a proposal for a program created by the Department of Architecture of the Faculty of Civil Engineering, which included an inner courtyard along with adjacent spaces, essentially covering the entire end section of Building D across both above-ground floors.

By roofing the entire courtyard, a large, open, almost industrial-looking hall is created - a factory for ideas, which is the leitmotif of the entire project. The free arrangement of workstations in the space respects the current needs of individual studios, allowing them to contract, expand, and integrate with other studios as the situation demands. Students do not shut themselves off with their mentors behind impenetrable walls. On the contrary, the opportunity to observe how ideas develop in other studios can be enriching for all.

This intent is the foundation of the overall concept of the reconstruction. The main emphasis was placed on the studios located both on the ground floor in the open hall space and on the southwest facade of the building for closeable studio rooms. The main two-story space is complemented by other operations necessary for the optimal functioning of the department.

Entrances to the atrium were positioned near the connecting bridge to Building "B" of the Faculty of Civil Engineering, and additionally, an alternative entrance directly from Kolejní Street was proposed at the location of the existing passage. This entrance, which was significantly architecturally designed, was intended to draw attention to the fact that something interesting was happening in this otherwise rather monotonous building. The entire reconstructed section was to satisfy the complete needs of students of architecture and create a compactly functioning whole.

However, this proposal was not realized in full extent due to operational and financial reasons, and the project already counted on significant limitations, with the scope of changes newly effectively defined by the outline of the original farmyard, in association with rooms on the 1st floor towards the southwest and northeast facades. Closed studio rooms, a computer room, and teachers' offices were removed from the program. A significant entry element was eliminated and replaced with a discreet barrier-free entry under the connecting link in the spirit of the ongoing door exchange throughout the faculty.

During the project's execution, many other minor or technological changes occurred; the most significant was probably the overall simplification of the air-conditioning provision of the space. The originally sophisticated air-conditioning and climate control system was replaced with a simpler and more economical design, relying more on natural ventilation and pre-cooling the space during the night hours in the summer months. Ultimately, the fact that students are on holiday during the hottest months of the year contributes to the feeling that this decision was correct.

Spatial Relationships

In the end, the realized space retained the most important aspect of the original concept, that open factory hall for ideas. The main entrance to the teaching space remained where Building D connects with Building C via a pedestrian bridge, either on the 1st floor directly into the studio spaces or to corridors and galleries on the 2nd floor, from where access is provided via suspended bridges to four hanging classrooms designated for teaching in smaller groups or consultations with a teacher. The open space on the 1st floor serves for any arrangement of six to eight studios, which are mutually separated by mobile furniture walls with lockable storage, allowing total space variability. All furnishings can be relatively easily relocated or rearranged so that new spaces or one large space are created that can be used for various purposes: exhibitions, lectures, conferences, state exams, social events. The adjacent longer walls are designed as exhibition areas for student work, while also serving an acoustic function. At the shorter sides, there are adjoining spaces - a respirium for relaxation and meeting, and on the other side, a technically equipped model-making room.

Daylight is provided through longitudinal skylights and glazed sides of the elevated roof structure. As protection against sunlight, external blinds are installed on the side glazing, and the polycarbonate closure of the skylights at the level of the ceiling provides the space with diffuse light.

Construction Solution, Technologies, and Materials Used

The load-bearing structure of the original building is a prefabricated reinforced concrete skeleton with a suspended facade and partitions predominantly made of ceramic masonry. The project envisaged the removal of the facade and moving layers of the inner courtyard and the installation of a new steel structure as independent as possible from the original structures.

The new steel structure consists of columns that are either founded on new base pads or on reinforced existing basement constructions. The columns carry connecting bridges on the 2nd floor, partially staircases, and primarily trussed girders forming the roof structure. Suspended from the roof are consultation boxes and also parts of staircases and bridges. The staircases are made of interconnected steel truss beams with sheet metal steps, which have anti-slip coatings. On the roof is a steel frame structure housing the ventilation machinery, clad in corrugated sheet metal that serves as an acoustic barrier.

In terms of design for materials and surface finishes of the interior, we adhered to the industrial and technical expression of the factory concept, aligning with the character of the adjacent halls. The foundation was rooted in simplicity and the naturalness of industrially appearing materials, without unnecessary surface treatments; the inner surfaces of ceilings and parts of walls are made of cement-bonded particleboards in a natural shade or galvanized expanded mesh that exposes the structure of the support profiles; the atrium is divided from neighboring rooms by copolymer walls or partitions with acoustic cladding from wood-fiber boards with textile wallpaper. The steel structure remained exposed and is a significant art component of the interior; the bridges leading to the suspended classrooms are also designed as visible steel constructions with perforated plates instead of traditional flooring. The character of the space is defined by four suspended classrooms formed by steel frames, clad with 22 mm thick special colored honeycomb polycarbonate sheets; the inner ceilings of these boxes are made of milky hollow polycarbonate to allow light to penetrate from the longitudinal skylights in the roof envelope. Fluorescent lights are incorporated into the cladding panels of the classroom structure, while other lights in the atrium are simply suspended in their "raw" visible form on troughs that distribute data and power cabling or in expanded mesh ceilings. All electrical wiring and air-conditioning are left exposed, thereby contributing to the overall design of the space. A new wire-reinforced concrete floor is implemented on the 1st floor, allowing for the movement of a three-ton cart for supplying the adjacent laboratories; on the 2nd floor, part of the floor is made of cement screed and part of studded rubber, while the consultation boxes have a floor made of glass panels.

Construction Implementation and Unforeseen Technological Issues

Since this was a reconstruction, we expected that the conditions for the construction would naturally be challenging. Especially since the construction took place under significant time pressure and that the construction documentation of the original project of the faculty, from which we had to work on the project, was not completely preserved and did not always correspond to the realities found directly during construction. A significant issue was the number of control and storage shafts located in the former courtyard space. Some were not depicted at all in the original drawing documentation and were hidden beneath loading layers, while for others, it was very difficult to ascertain the load-bearing capacity of their ceiling. Another problem was the replacement of the original freight elevator with a new passenger one, as the internal dimensions of the shaft did not match the expected dimensions, which posed certain challenges in the short timeframe needed to manufacture and prepare the elevator technology. In the removed facade cladding, asbestos was discovered, which complicated the technological aspect and prolonged construction time. The facade had to be secured from the inside and outside before dismantling to prevent contamination of the surrounding environment. Moreover, the entire construction was carried out while the school was fully operational and even in rooms that were still in use during construction. For example, in the room of the adjacent laboratory, a long-term geotechnical experiment requiring a stable thermal environment was ongoing, which could not be moved from this room, and we routed new ventilation through it while removing the asbestos-containing facade cladding. Due to this time-space collision, the original material solution of the load-bearing partition had to be replaced from masonry to a steel structure with drywall cladding to avoid wet construction processes.

We were disappointed by the technical problems with the cladding panels made of colored polycarbonate Bencore, intended for the walls of the suspended classrooms. Our initial idea that the panels would be attached to the steel structure using only high-strength double-sided adhesive tape (according to the manufacturer's static data, this solution should be fully sufficient) evaporated the moment the panels began to disintegrate after attaching the first pieces. According to the manufacturer, this was caused by the selected atypical color of the face panels made of plexiglass. The supplier of the sandwich panels re-glued them at their own expense, but trust in their proclaimed excellent static properties was lost, and the panels, which were originally meant to function as solid walls of the boxes, were instead secured with screws to ensure the glued connections. For safety reasons, the inner sides of these walls will also be equipped with handrail bars.

A minor challenge was resolving the surfaces of two steel staircase ramps in the atrium space. The trussed structure is clad in aluminum sheets painted in high-gloss black powder coating, which are also adhered with high-strength double-sided adhesive tape (with securing screws), but the problem arose with the metal steps, whose treads needed to exhibit sufficient and guaranteed anti-slip properties. After a long search, the supplier managed to find a manufacturer of anti-slip coatings for sheet metal, though we were surprised that it is a relatively unique product in its category.

Despite all the difficulties,

The English translation is powered by AI tool. Switch to Czech to view the original text source.

11 comments

add comment

Subject

Author

Date

Na pohled bez chyby

pavelschn

29.10.08 06:47

RE:

jana

30.10.08 09:17

Mohu jen potvrdit..

_merlin_

30.10.08 10:49

Re

misssunny3

30.10.08 02:57

vada na kráse

schn

30.10.08 07:35

show all comments