Freedomek M: free housing with FERMACELL materials

In the second half of August, a new presentation Freedomek was opened in Zlín, near the film studios, designed by architect Marek Štěpán from the company Freedomky s.r.o. Brno. The Zlín object, designated as Freedomek M (medium), represents a new generation of houses from the portfolio of the domestic leader and market creator in the field of free housing. The fundamental structural material for this new Freedomek is FERMACELL fiber gypsum boards and FERMACELL Vapor.

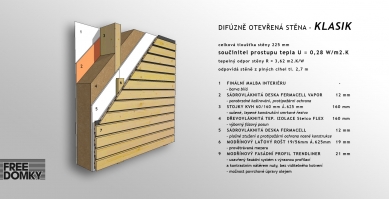

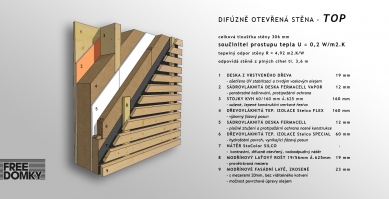

Their properties and installation method ensure that the compositions of the Freedomek's outer shell (walls, roof, floor) are diffusion-open and fire-resistant. Thanks to the special lamination on the back of the FERMACELL Vapor boards, the permeability of water vapor is reduced to such an extent that additional vapor-proof layers in the outer wall constructions are eliminated. At the same time, the excellent properties of the original FERMACELL fiber gypsum board as a biologically safe construction board, fire-resistant board, and board for humid areas are preserved. The equivalent diffusion thickness sd > 3 m allows the FERMACELL Vapor fiber gypsum board to be used as internal cladding (in Freedomeks at the ceilings) or as a cladding for timber-based structures (in Freedomeks on the outer walls).

Wall and ceiling compositions

wall (from the inside)

FERMACELL Vapor 12.5 mm

wooden stud frame 60*140

FERMACELL 12.5

diffusion-open facade with wood fiber insulation, wooden larch frame

ceiling (from the inside)

FERMACELL Vapor 12.5 mm

wooden frame

ceiling structure with insulation

ventilated gap

OSB board as a carrier of the covering

covering - bitumen membrane

The new generation of Freedomek M represents a return to the roots of living, top technology processing, the best natural materials in conjunction with low operating costs and environmental friendliness. In creating the Freedomek, architect Marek Štěpán emphasized the quality of the materials used and the comfort of living, including the costs of its acquisition and operation. Instead of various "pseudo-ecological" technologies that are inefficient within specific solutions, rather inflate the project costs and merely follow appealing trends, the new generation of Freedomeks includes technologies that offer nearly maintenance-free and cost-free living to the user. Energy savings during heating are ensured by the thermal insulating properties of the wall, whose thickness of 30 cm corresponds to the thermal insulating properties of a brick wall 3.6 meters thick. The Freedomek is made 95 percent from wood, with insulation made of natural wood fiber insulation Steico FLEX, which insulates excellently but is also naturally resistant to degradation and settling. Its bulk density also has a very positive effect on the so-called phase shift, and thus thermal comfort indoors. The facade of the house is made of Nordic larch.

The first owner of the Freedomek in Mýtě near Tachov is Ing. Martin Turner, who is also its contractual manufacturer. His sawmill B.Turner s.r.o. has produced more than 10 homes of various sizes, equipment, and constructions since the start of the project. The house with serial number 001 was manufactured by Mr. Turner for his family and he is extremely satisfied with it. He particularly appreciates the freedom the Freedomek provides, which does not only include the possibility of installing the house anywhere you want, but primarily the fact that one does not become a slave to the house. Maintenance is easy and takes minimal time, and operating costs are also very low. As a person from the industry, he appreciates the quality of execution; the construction is made from very high-quality materials. "Where other companies stop with quality in wooden buildings, Freedomeks begin", says Martin Turner.

The newly opened showroom Freedomek M in Zlín, with an area of 48 m², is offered by the manufacturer in its basic version for 998,000 CZK without VAT; at this price, the customer receives a completed turnkey house including electric heating, vinyl flooring, and a fully equipped bathroom.

The company Freedomky utilizes the support of the JIC Innovation Park, which won 3rd place in the global competition The Best Incubator Award in the category of Best Internationally Engaged Incubator for 2011. Thanks to the processing technology, the quality of materials used, and its innovative approach, Freedomky has solidified its position as a market leader and creator in the field of free housing with its own development and technological and intellectual background within a year of operating in the market. The project author is Moravian architect Marek Jan Štěpán, who won 1st place in the Grand Prix Architects 2012 competition in the category of "reconstruction." The Local Architects' Association awarded him for the Café Fara project in May of this year.

Their properties and installation method ensure that the compositions of the Freedomek's outer shell (walls, roof, floor) are diffusion-open and fire-resistant. Thanks to the special lamination on the back of the FERMACELL Vapor boards, the permeability of water vapor is reduced to such an extent that additional vapor-proof layers in the outer wall constructions are eliminated. At the same time, the excellent properties of the original FERMACELL fiber gypsum board as a biologically safe construction board, fire-resistant board, and board for humid areas are preserved. The equivalent diffusion thickness sd > 3 m allows the FERMACELL Vapor fiber gypsum board to be used as internal cladding (in Freedomeks at the ceilings) or as a cladding for timber-based structures (in Freedomeks on the outer walls).

Wall and ceiling compositions

wall (from the inside)

FERMACELL Vapor 12.5 mm

wooden stud frame 60*140

FERMACELL 12.5

diffusion-open facade with wood fiber insulation, wooden larch frame

ceiling (from the inside)

FERMACELL Vapor 12.5 mm

wooden frame

ceiling structure with insulation

ventilated gap

OSB board as a carrier of the covering

covering - bitumen membrane

The new generation of Freedomek M represents a return to the roots of living, top technology processing, the best natural materials in conjunction with low operating costs and environmental friendliness. In creating the Freedomek, architect Marek Štěpán emphasized the quality of the materials used and the comfort of living, including the costs of its acquisition and operation. Instead of various "pseudo-ecological" technologies that are inefficient within specific solutions, rather inflate the project costs and merely follow appealing trends, the new generation of Freedomeks includes technologies that offer nearly maintenance-free and cost-free living to the user. Energy savings during heating are ensured by the thermal insulating properties of the wall, whose thickness of 30 cm corresponds to the thermal insulating properties of a brick wall 3.6 meters thick. The Freedomek is made 95 percent from wood, with insulation made of natural wood fiber insulation Steico FLEX, which insulates excellently but is also naturally resistant to degradation and settling. Its bulk density also has a very positive effect on the so-called phase shift, and thus thermal comfort indoors. The facade of the house is made of Nordic larch.

The first owner of the Freedomek in Mýtě near Tachov is Ing. Martin Turner, who is also its contractual manufacturer. His sawmill B.Turner s.r.o. has produced more than 10 homes of various sizes, equipment, and constructions since the start of the project. The house with serial number 001 was manufactured by Mr. Turner for his family and he is extremely satisfied with it. He particularly appreciates the freedom the Freedomek provides, which does not only include the possibility of installing the house anywhere you want, but primarily the fact that one does not become a slave to the house. Maintenance is easy and takes minimal time, and operating costs are also very low. As a person from the industry, he appreciates the quality of execution; the construction is made from very high-quality materials. "Where other companies stop with quality in wooden buildings, Freedomeks begin", says Martin Turner.

The newly opened showroom Freedomek M in Zlín, with an area of 48 m², is offered by the manufacturer in its basic version for 998,000 CZK without VAT; at this price, the customer receives a completed turnkey house including electric heating, vinyl flooring, and a fully equipped bathroom.

The company Freedomky utilizes the support of the JIC Innovation Park, which won 3rd place in the global competition The Best Incubator Award in the category of Best Internationally Engaged Incubator for 2011. Thanks to the processing technology, the quality of materials used, and its innovative approach, Freedomky has solidified its position as a market leader and creator in the field of free housing with its own development and technological and intellectual background within a year of operating in the market. The project author is Moravian architect Marek Jan Štěpán, who won 1st place in the Grand Prix Architects 2012 competition in the category of "reconstruction." The Local Architects' Association awarded him for the Café Fara project in May of this year.

The English translation is powered by AI tool. Switch to Czech to view the original text source.

1 comment

add comment

Subject

Author

Date

freedomek - dispozice

s.j.k.

22.10.12 05:12

show all comments

Related articles

0

18.06.2013 | Smart combination of wood, concrete, and fermacell in seven-story residential buildings in Berlin

1

03.06.2013 | A new kindergarten in Jesenice near Prague has been built thanks to UNIKO modules

0

29.04.2013 | Austrian architect bet on wooden construction RD Rýmařov with fermacell materials

2

01.11.2012 | Cheap, fast, and economical wooden medical center construction in Mníšek near Liberec with FERMACELL materials

0

17.05.2011 | Breathe deeply and healthily with FERMACELL greenline

2

12.10.2010 | Low-energy family houses on Arbesova Street in Olomouc - quality and healthy living with FERMACELL materials