Modular background for Golf Lozorno

Modular construction, thanks to its mobility, is ideal for temporary structures, whether it concerns facilities for concerts and festivals, cabins, temporary family homes, or facilities for sports areas. The realization of Golf Lozorno near Bratislava demonstrates that modular construction can be architecture with quality design and unparalleled speed of construction.

KOMA MODULAR CONSTRUCTION has long been dedicated to building awareness of modular architecture. Its goal is not only to convince both professionals and the general public of the benefits of modular construction but also to showcase its product lines, demonstrating the quality and variability of the system. The M3 series consists of modules that meet the architectural and technical quality requirements of even the most demanding clients in terms of energy efficiency and design as well as interior equipment.

As examples of new attractive implementations in the Czech Republic, we can mention the areas of Golf Marina Prague and Golf Letňany. In our Slovak neighbors, it is the Golf Pegas in Lozorno near Bratislava, which captures attention with its outer shell at first glance.

Modular buildings have a significant advantage in façade choice. For the M3 series, absolutely any cladding material can be used, which is attached to the load-bearing structure via a wooden framework. This allows for a variable character of the building, dependent only on the customer's wishes—from high-tech stainless steel sheets to minimalist fiber cement boards, and up to warm natural materials like those mentioned in the realizations near Bratislava. In this case, the outer skin features cladding made of Thermowood from steamed pine.

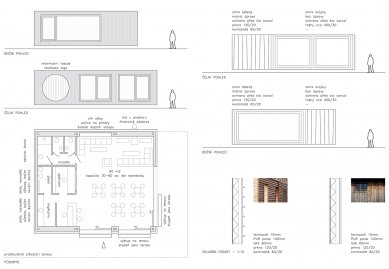

In addition to the cladding material, another advantage of the KOMA system is the high variability in designing the size and arrangement of doors and window openings. The only limitation here is the beams of the perimeter frame structure, so in the longitudinal direction of the longest module, measuring 9 meters, it is theoretically possible to create a glass wall without interruption. In the specific case of the Golf Lozorno facility, French windows measuring 3064 x 2500 mm were used. Their application successfully dispels the prejudices of gloominess associated with the word "container" and instead creates a sense of spaciousness in the interior. Thus, the building transforms into an exhibition pavilion, the windows of which are additionally equipped with electric external blinds.

The sense of spaciousness is further supported by the fact that the composition of several modular elements and their interaction creates a space with a span of 9 meters, which does not require any supporting columns inside. The KOMA modular system allows for an endless arrangement of containers side by side. For the M3 type, it is therefore possible to create an open hall space with a width of 9 m and depth limited only by the length of the escape route, as determined by fire safety standards. The entire assembly in the case of the Lozorno implementation includes a large common room, a reception with a kitchen, an office, a technical room, a changing room, and 2x restrooms (male and female) with a shower.

Ceramic tiles are used as the surface material on the floor, which is one of the many variations that this modular system allows. KOMA also offers concrete floors for its prefabricated buildings, which can have a thickness ranging from 70 to 200 mm. This eliminates the unpleasant feeling of a "hollow" floor, giving the building the qualities of a traditional structure without compromising any of the mobility advantages.

For even higher interior brightness, the inner walls are covered with Fermacell fiber cement boards, coated with a white finish. The KOMA system allows for the use of ceramic tiles on both the floor and all walls and partitions, which is utilized in the bathroom and restroom areas. The lighting is provided by recessed LED spotlights embedded in the ceiling. Heating is accomplished through a combination of electric heaters and a wood stove.

The speed of construction is evidenced by the fact that the manufacturer guarantees delivery of the building within three months from the order. After that, the building is set in place. In this case, on 16 concrete bases, around which an outdoor terrace will be built, reaching the level of the module's lower frame. This is planned for September, along with furnishing the assembly with furniture. The main advantage of this solution, compared to traditional construction, is the incomparable speed of realization, which is a critical characteristic in today’s modern era and decisive for most investors.

KOMA MODULAR CONSTRUCTION has long been dedicated to building awareness of modular architecture. Its goal is not only to convince both professionals and the general public of the benefits of modular construction but also to showcase its product lines, demonstrating the quality and variability of the system. The M3 series consists of modules that meet the architectural and technical quality requirements of even the most demanding clients in terms of energy efficiency and design as well as interior equipment.

As examples of new attractive implementations in the Czech Republic, we can mention the areas of Golf Marina Prague and Golf Letňany. In our Slovak neighbors, it is the Golf Pegas in Lozorno near Bratislava, which captures attention with its outer shell at first glance.

Modular buildings have a significant advantage in façade choice. For the M3 series, absolutely any cladding material can be used, which is attached to the load-bearing structure via a wooden framework. This allows for a variable character of the building, dependent only on the customer's wishes—from high-tech stainless steel sheets to minimalist fiber cement boards, and up to warm natural materials like those mentioned in the realizations near Bratislava. In this case, the outer skin features cladding made of Thermowood from steamed pine.

In addition to the cladding material, another advantage of the KOMA system is the high variability in designing the size and arrangement of doors and window openings. The only limitation here is the beams of the perimeter frame structure, so in the longitudinal direction of the longest module, measuring 9 meters, it is theoretically possible to create a glass wall without interruption. In the specific case of the Golf Lozorno facility, French windows measuring 3064 x 2500 mm were used. Their application successfully dispels the prejudices of gloominess associated with the word "container" and instead creates a sense of spaciousness in the interior. Thus, the building transforms into an exhibition pavilion, the windows of which are additionally equipped with electric external blinds.

The sense of spaciousness is further supported by the fact that the composition of several modular elements and their interaction creates a space with a span of 9 meters, which does not require any supporting columns inside. The KOMA modular system allows for an endless arrangement of containers side by side. For the M3 type, it is therefore possible to create an open hall space with a width of 9 m and depth limited only by the length of the escape route, as determined by fire safety standards. The entire assembly in the case of the Lozorno implementation includes a large common room, a reception with a kitchen, an office, a technical room, a changing room, and 2x restrooms (male and female) with a shower.

Ceramic tiles are used as the surface material on the floor, which is one of the many variations that this modular system allows. KOMA also offers concrete floors for its prefabricated buildings, which can have a thickness ranging from 70 to 200 mm. This eliminates the unpleasant feeling of a "hollow" floor, giving the building the qualities of a traditional structure without compromising any of the mobility advantages.

For even higher interior brightness, the inner walls are covered with Fermacell fiber cement boards, coated with a white finish. The KOMA system allows for the use of ceramic tiles on both the floor and all walls and partitions, which is utilized in the bathroom and restroom areas. The lighting is provided by recessed LED spotlights embedded in the ceiling. Heating is accomplished through a combination of electric heaters and a wood stove.

The speed of construction is evidenced by the fact that the manufacturer guarantees delivery of the building within three months from the order. After that, the building is set in place. In this case, on 16 concrete bases, around which an outdoor terrace will be built, reaching the level of the module's lower frame. This is planned for September, along with furnishing the assembly with furniture. The main advantage of this solution, compared to traditional construction, is the incomparable speed of realization, which is a critical characteristic in today’s modern era and decisive for most investors.

The English translation is powered by AI tool. Switch to Czech to view the original text source.