The top testing center of VEKA monitors the quality of plastic profiles

The quality of plastic windows is fundamentally influenced by three factors – whether they contain insulating double or triple glazing, the fittings, and the profile used for their production. The profile plays an important role because it supports heavy glass, serves to mount the fittings, and significantly contributes to sound insulation. VEKA's profiles are fundamentally manufactured only in the highest class A, as defined by the European standard ČSN EN 12608, and their quality is regularly monitored by VEKA. In its testing center, it regularly conducts more than 25 load tests on profiles as well as windows and doors made from them.

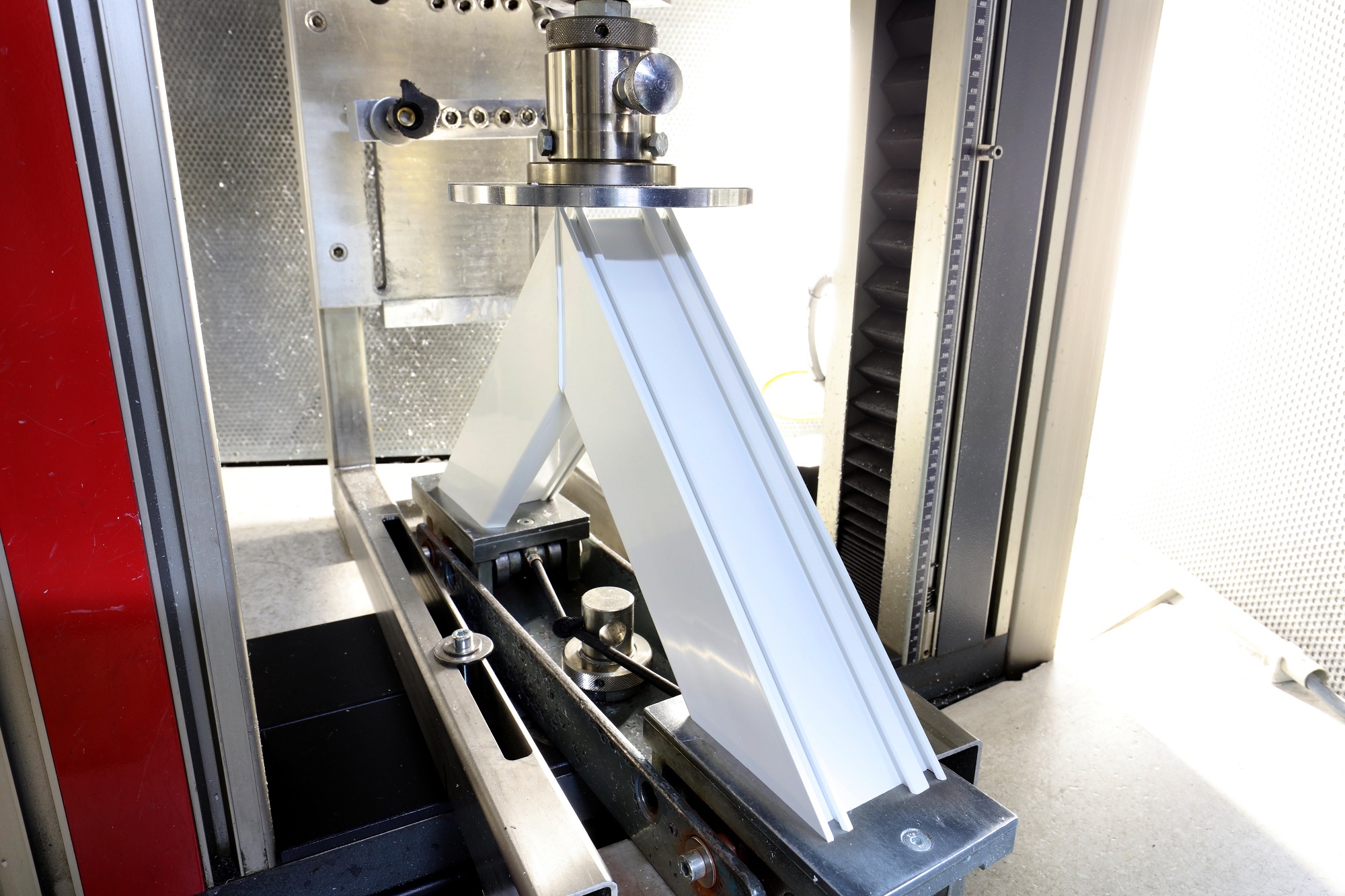

Test of the corner stability of VEKA profile

When selecting a window, the price you are willing to pay will always matter. You must answer the classic question – do you want a quality product or a cheap one? In the case of windows made from class A profiles, you are indeed paying for quality, but the higher price will be returned to you in longevity and thermal comfort. And what exactly are you paying for? The answer can be found using the standard “ČSN EN 12608 - Profiles made of unplasticized polyvinyl chloride (PVC-U) for the manufacture of windows and doors”. This defines the individual profiles including the parameter that manufacturers of class B and C profiles often "forget" to mention when defending the quality of their products. This refers to the wall thickness, which affects the stability and lifespan of the window.

Class A Profiles are a Bet on Quality

The European standard ČSN EN 12608 classifies profiles into classes based on the thickness of the outer wall as follows:· class A (outer wall thickness 3.0 mm; tolerance +/- 0.2 mm)

· class B (outer wall thickness 2.7 mm; tolerance +/- 0.2 mm)

· class C (outer wall thickness 2.5 mm; no tolerance)

The question naturally arises whether a difference of 0.3 mm between classes A and B in outer wall thickness is that significant. We can seek the answer in the results of load tests conducted by VEKA in its testing center. This center in Sendenhorst, Germany, participates in the development of new products and the ongoing quality control of its manufactured portfolio. Based on measurements and load tests in the mentioned center, comparisons between classes A and B can highlight differences such as load-bearing capacity and corner strength, where the welded areas in class A profiles demonstrate 20% higher values. This difference is mainly due to the overall mass of the material used for production, where a window with the same view area uses up to 14% less material in a class B profile. Class A profiles also perform significantly better in shape stability tests. Deflection and twisting are up to 12% lower than those of class B. The requirement to exert 20% more force to pull screws from class A profiles is an interesting difference for mounting the fittings.

|

VEKA Profile Quality is Monitored by Over 25 Load Tests

The testing center mentioned performs more than 25 load tests on windows and doors, among which, in addition to the aforementioned shape stability and load-bearing tests, we also find verification of the long-term functionality of window opening. In this test, the window is subjected to mechanical stress through repeated opening and closing. The tested product must achieve class 2 according to the requirements of the DIN EN 12400 standard and withstand 10,000 cycles without damage, deformation, or loss of functionality.

Similarly, vertical load and static twisting are tested, verifying the resistance against improper handling by users according to the DIN EN 14608 standard. The load here acts perpendicularly on the outer free corner of the sash frame, and the window must not lose any of its ability to open and close, nor may there be any loosening of joints, fittings, or seals.

Windows are also tested for water resistance, and within this, water penetration is tested in individual steps of 0.5 m. During the load test, the water level is maintained for 24 hours with a maximum deviation of 20 mm and an inflow that does not drop below 240 liters.

“Our testing center in Germany does not only perform tests on components and materials of windows and doors, but also participates directly in the development and manufacturing processes. Thanks to the center, we can guarantee our customers the parameters and high quality of our class A profiles and document their advantages,” says Milan Klepsa, the main representative of VEKA for the Czech Republic and Slovakia.