Passive timber construction - we have consumption under control

And what was the energy balance of this winter?

“Experiences from this winter are very good. At first, it didn't look very good; December was very cold and gloomy.” The actual temperature hovered around minus 4.5 °C (while the average in the coldest month, January, is minus 2.2 °C!), so this month was indeed a test. “December's consumption amounted to 800 kWh, of which 300 kWh was for heating water and 500 kWh for heating. However, by the end of February, the sun started shining, so we more or less stopped heating. In March and April, we fully covered the hot water consumption with solar energy,” the couple praises. The solar collectors heat a 900-liter integrated heat storage tank to 95 °C. Thanks to insulation, the tank can supply heat for an entire week of cloudy weather. The warm air heating system operated without a radiant component – radiators – and heats the house to 22 °C.

Controlled ventilation according to individual requirements

The house is equipped with a ventilation (recuperation) unit with stronger fans, whose lower speeds also guarantee lower noise levels. The owner has adjusted the air conditioning according to individual requirements, with options for two levels of speed: medium and maximum – although the system is designed for maximum, medium speed is sufficient for the house. “At 120 RPM, it's possible to heat the house even if it's minus 15 °C outside, and there is still a third reserve, so heating can be intermittent,” he says. “The only problem at minus 15 °C was the condensation on the windows, which increased humidity in the house. It hovers around 55%, which is normal. The house is still drying out, so over time it will show what caused the humidity.”

Passive wooden building in 6 months

Builders who previously lived in a brick apartment building contemplated the construction of a wooden passive house for three years. Eventually, they entrusted their project to the company KARON and placed their trust in the NOVATOP construction system. Construction took place from January 2010 until approximately the end of April/beginning of May, and within six months, the wooden building was handed over for use.

With the NOVATOP technology, assembly is quick, precise, and simple; the construction arrived fully prepared down to the details. For the successful implementation and especially for the proper functioning of the passive wooden building, precision and thorough execution of all construction details are very important, which goes hand in hand with the total number of assembly joints. Both of these have a significant impact on airtightness, which is a very important criterion for passive and energy-efficient wooden buildings. “The NOVATOP panels produced with an accuracy of two-tenths of a millimeter leave nothing to be desired in this regard. This is confirmed by the airtightness test (Blowerdoor test), which for this house reached a value of 0.14 h-1, which is about a quarter of the required standard and thus ranks at the top in the country,” shared his experiences Stanislav Karásek, owner of the company KARON, which has been building passive houses since 2003 and has been working with the NOVATOP system for the third year as a certified partner.

The entire rough construction of the house was completed in four days

On the first day, the load-bearing exterior structure made of NOVATOP panels was erected, which was subsequently supplemented with two layers of polystyrene; the roof trusses were assembled over the next two days, and on the fourth day, the roof was covered with OSB boards. Other external and internal finishes proceeded without any complications. The builder was able to regularly commute to the construction site and even contributed labor himself, so the electrical work in the house was partly done as a DIY project. “Thanks to the responsible approach of the construction company, it was possible to complete a family house in a short time, with which we are extremely satisfied in terms of quality and especially passive standards,” the owners unanimously say.

Energy balance in numbers

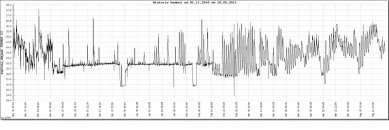

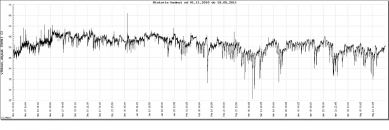

From the following graphs and especially the table, it is clear that heating in the house began in mid-November 2010, with the highest energy consumption recorded in December, when outdoor temperatures averaged more than 3.5 degrees below the temperatures for which the warm air heating was designed. "The heating season" in the true sense of the word practically ended already in March, when the solar panels on the roof started functioning fully. These were sufficient in the following month to cover all the heating needs in the house.

|

more at: http://www.novatop-system.cz/