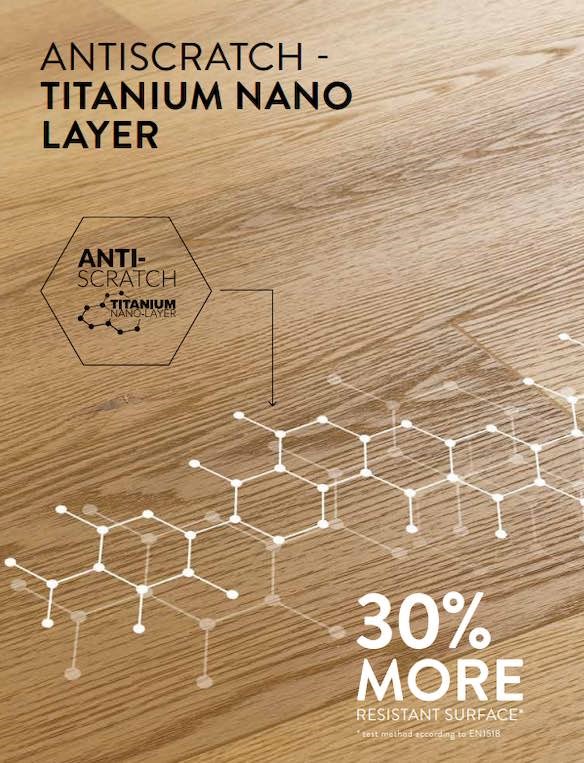

The SPC flooring collection Arbiton is protected by space-resistant nanotechnology

You won't see the protective layer Titanium Nano Layer under a microscope, but thanks to a dish sponge, you will notice the difference in scratch resistance with the naked eye.

The Titanium Nano Layer technology has descended from space to Earth, specifically to SPC Arbiton floor coverings, increasing the scratch resistance of these mineral floors by thirty percent. The technology, working with particles in the order of billionths of a meter (10-9), cannot be seen even under a microscope. However, if you take a sponge and "scratch" two floors, one without and one with the Titanium Nano Layer protective coating, you will see the difference in scratching with the naked eye.

|

Floors protect against scratching at the atomic level

The Titanium Nano Layer protective coating operates at an atomic level. “The covering is treated with a lacquered layer that, due to the nano size of the particles, permeates even the smallest micro pores of the covering, which are not visible even under a microscope. A nanometer is one-billionth of a meter, or 10-9 meters, which is unimaginably small. But it is this micro part of the liquid that seeps into the smallest joints. And by filling these tiny pores, it increases the floor’s resistance to scratching by up to thirty percent,” explains Milan Mrkáček, outlining the principle of operation. In contrast, the structure of conventional lacquer is much larger, so ordinary lacquer remains only on the surface of the covering, does not penetrate inside, and thus has lower resistance.

And what about cats?

Even though cats scratch just about everything, the resistance of the Titanium Nano Layer protective coating is visible at first glance even after a cat attack. The effectiveness of the protection can be demonstrated, for example, with a dish sponge. “If you were to try to scratch a regular vinyl or SPC with the rough side of a sponge and then do the same intensity on a floor with the Titanium Nano Layer, you would see a total difference,” adds Milan Mrkáček from KPP.

The manufacturer of mineral coverings Arbiton first protected its Arbiton Liberal collection (11 oak and 1 walnut designs) and Arbiton Amaron (oak decors in the Wood collection and stone in the XXL Stone Design collection) with a nano layer. Now, the Titanium Nano Layer is standard in all Arbiton SPC coverings, including the new Herringbone collections (in fishbone design) and Superiore (with Synchrostructure surface treatment with a real wood surface).

It is also noteworthy that Arbiton operates not only as a manufacturer but also as a testing laboratory. “Before they started manufacturing floors themselves, they tested them, which gave them rich experiences and a good understanding of what works and what to avoid,” reveals Milan Mrkáček from KPP.