The latest products in the plastics division will be presented by Schüco at the Fensterbau/Frontale 2012 trade fair in Nuremberg

Plastic window and door profiles Schüco ThermoPlus and ThermoSlide for energy-efficient housing

From March 21 to 24, 2012, leading global window manufacturers and experts will meet in Nuremberg, Germany, at the international trade fair fensterbau/frontale 2012. Among the exhibitors will be a presentation from Schüco, a leading global player in the field of building envelopes and solar technologies, with booth number 503 located in hall 7. In addition to showcasing new products in the range of plastic profiles, the company, in accordance with the Energie³ strategy - saving, producing, and distributing energy/utilizing, will emphasize the importance of a positive energy balance in buildings and efficient energy management.

For more information, visit www.schueco.cz

Schüco AutomotiveFinish - highly durable surfaces for plastic profiles

The quality surface finish of window and door profiles is among the highly valued criteria. Surface treatment prevents the window from being susceptible to damage from climatic influences, and additionally, when choosing a different shade, it can express the exclusivity and uniqueness of the given object. Besides the resistance of profiles to adverse weather conditions and other chemical and mechanical influences, clarity and color stability are also among the qualitative characteristics. These and many other requirements were taken into account by Schüco's technicians during the development of the surface finishing technology Schüco AutomotiveFinish, a novelty presented exclusively at the fensterbau/frontale fair. Inspiration came from experiences and know-how garnered in the automotive industry. The result is bright metallic surfaces with high resistance to corrosion and chemicals, meeting demanding technical standards. With the new coloring technology, Schüco brings broad possibilities for the future use of plastic profiles to the market. Several samples will be available for visitors to view on-site.Schüco ThermoPlus and ThermoSlide plastic profiles with excellent insulation properties

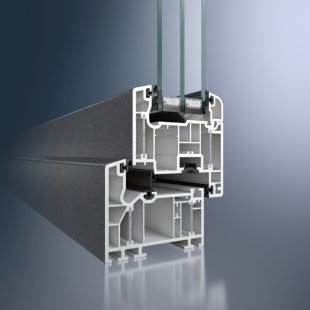

There will, of course, be information and materials regarding the entire portfolio of plastic profiles that the company has been manufacturing for over 30 years. However, particular attention should be paid to the new window system without steel reinforcements Schüco ThermoPlus with a construction depth of 82 mm. The profile offers an improved thermal insulation value (Uf from 0.79 W/m²K) and broader possibilities for usage. The sash is designed for larger dimensions and allows for optional glazing of the glass in the rebate of the sash profile. The company is further expanding its range with the introduction of Schüco ThermoSlide lift-and-slide door system. This system, with a load capacity of up to 400 kg and triple glazing, guarantees optimal thermal insulation values. The outer frame with a construction depth of 82 mm ensures maximum tightness and thermal insulation, while the flat aluminum threshold is thermally separated. The average heat transfer coefficient of the frame reaches a value of 1.1 W/m²K.Attractive price-quality ratio

For many years, Schüco's plastics division has been based in the German city of Weißenfels (Saxony-Anhalt region). Here, all processes take place, from management and development to the purchase of raw materials, production, and sales and distribution. This division, which achieved a turnover of 220 million Euros last year, employs approximately 820 employees. The fully automated factory with raw material recycling systems and 34 production lines is among the most modern in Europe. The warehouse space, covering approximately 46,000 m², accommodates over 3,200 types of plastic profiles. Both smaller and larger orders can thus be realized within minimal delivery times. The premises also contain storage for steel reinforcements, hardware, and other accessories. Schüco's plastic window and door profiles offer an attractive price-quality ratio, guaranteeing excellent thermal insulation values. PVC-U material, characterized by high strength and dimensional stability, represents an environmentally friendly, stable, and recyclable material. The profiles meet the requirements for safety, user comfort, design, and energy efficiency.For more information, visit www.schueco.cz

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment

Related articles

0

22.07.2013 | New plastic system for windows Schüco Alu Inside without steel reinforcements

0

17.06.2013 | A new production hall for colored plastic profiles of the company Schüco was opened in Weißenfels, the headquarters of the plastics division

0

22.05.2012 | Plastic systems with Schüco AutomotiveFinish surface treatment received metallic colors known from the automotive industry

0

23.02.2012 | Integrated window ventilation system Schüco VentoTherm with air recovery, filter, and automated control